- Spring 2025

Optimizing Recycled Plastics for Use in Asphalt Applications

NCAT recently completed the National Cooperative Highway Research Program (NCHRP) project 09-66, which evaluated the impact of post-consumer recycled (PCR) plastics on the performance properties of asphalt mixtures via the dry process. Phase I involved a comprehensive literature review to build upon previous efforts documented in NAPA IS-142. This review summarized existing studies and identified knowledge gaps on the availability and sourcing of recycled plastics; methods of incorporating recycled plastics; laboratory characterization of recycled plastic modified (RPM) asphalt binders and mixtures; plant operations; construction; health and safety; environmental impacts; field project performance; and other potential civil engineering applications.

Phase II addressed several knowledge gaps identified in the literature review through a detailed laboratory work plan. This plan included five key experiments: 1) characterizing the critical properties of recycled plastics for use in asphalt mixtures, 2) evaluating the performance properties and surface characteristics of plant-produced RPM mixtures versus control mixtures without recycled plastics from two field projects, 3) exploring the use of a near-infrared spectrometer for quality control testing of PCR plastics, 4) evaluating different laboratory procedures for adding PCR plastics to simulate the production of dry-process RPM mixtures at asphalt plants, and 5) characterizing the performance properties of laboratory-prepared RPM mixtures with different sources and types of PCR plastics. The most significant findings and conclusions of the project are summarized below.

Property Characterization of Recycled Plastics

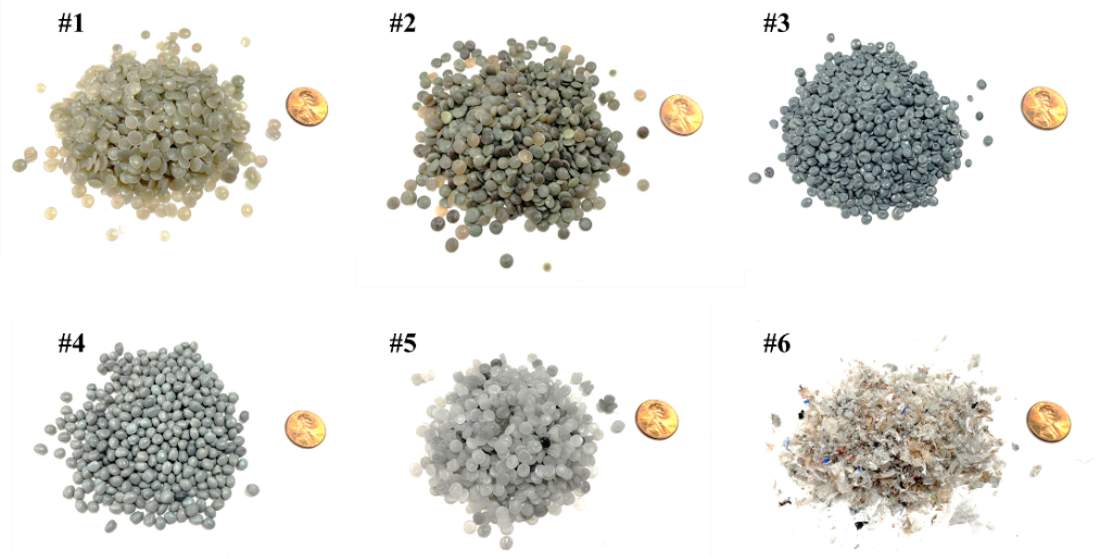

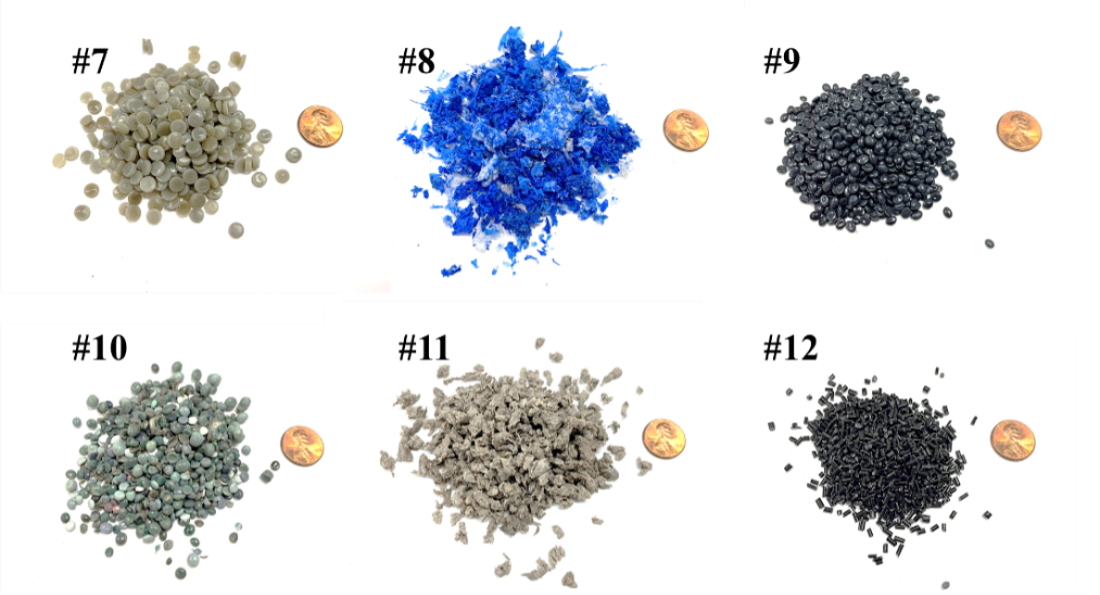

Analytical characterization of twelve PCR plastic samples from different sources (Figure 1) revealed a wide range of physical, thermal, and chemical properties. All samples, except one, had an initial melting temperature between 121°C and 164°C, which is either below or within the typical production temperature range of asphalt mixtures. A few samples exhibited high fume and emission potential, and one sample contained detectable benzene, raising potential safety concerns for use in asphalt. These findings underscore the complexity of PCR plastics and the necessity to regulate their sources and properties to ensure material consistency and safety for potential use in asphalt mixtures.

Figure 1. Pictures of PCR Plastic Samples Evaluated in NCHRP Project 09-66

Impacts of Dry-process PCR Plastics on Asphalt Mixture Properties

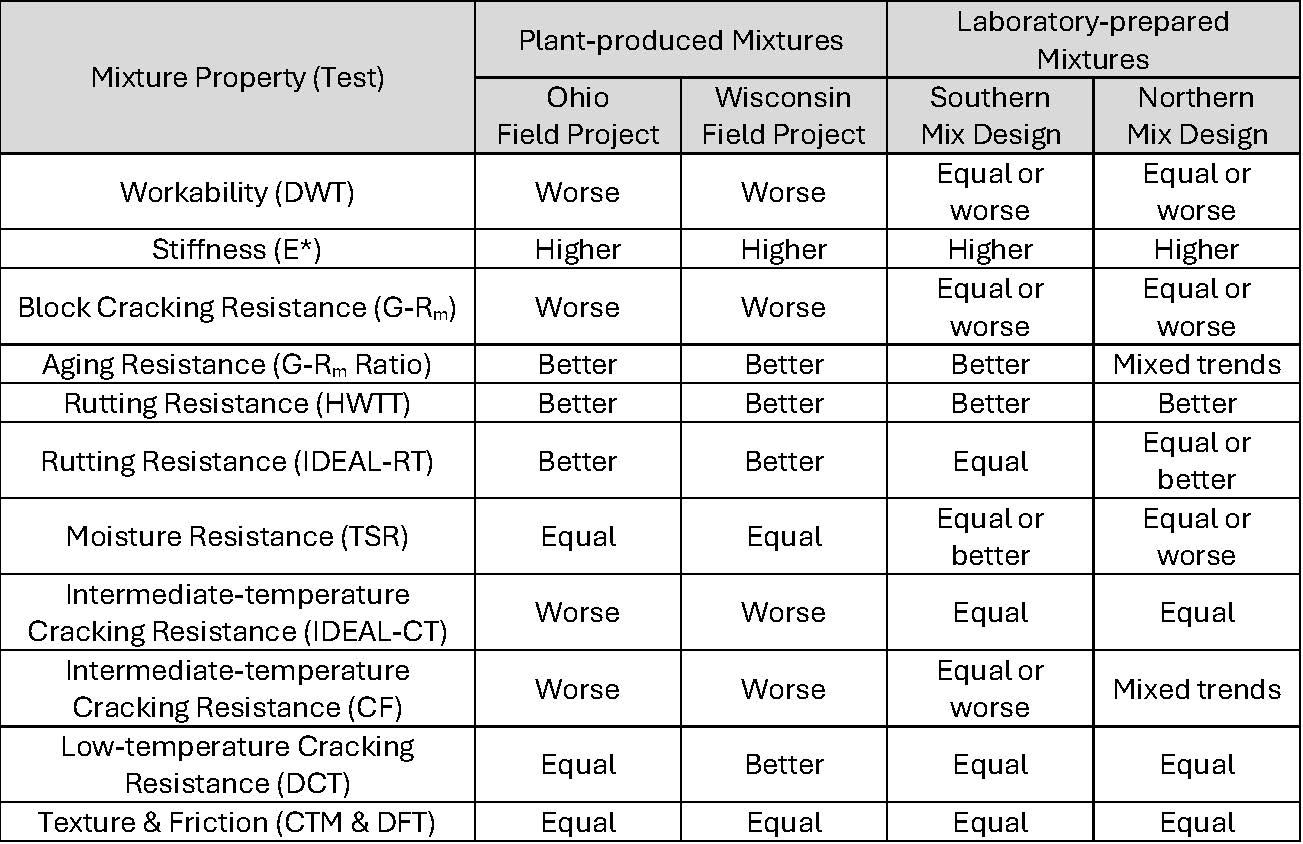

Table 1 compares dry-process RPM asphalt mixtures to control mixtures without PCR plastics. Adding PCR plastics increases stiffness and rutting resistance but reduces workability, intermediate-temperature cracking resistance, and block cracking resistance, with effects varying by melt flow index. PCR plastics have minimal impact on low-temperature cracking resistance, surface texture, and friction. Moisture susceptibility varies by mix design and needs further study. Since cracking is the most common distress in U.S. asphalt pavements, adding dry-process PCR plastics without other mix modifications is unlikely to improve performance.

Table 1. Property Comparison of Dry-process RPM Mixtures Compared to Control Mixtures

Impacts of Dry-process PCR Plastics on Asphalt Binder Properties

Adding PCR plastics via the dry process does not significantly affect the rheological and chemical properties of extracted asphalt binders. However, this finding should be interpreted cautiously, as it could be confounded by the lack of solubility of PCR plastics in asphalt extraction solvents.

Laboratory Method of Adding PCR Plastics using the Dry Process

Different methods of adding PCR plastics in the lab affect RPM asphalt mixtures' performance due to varying thermal conditions during mixing. The four evaluated methods did not release significant hazardous fumes or polycyclic aromatic hydrocarbons but failed to produce lab-prepared RPM mixtures matching plant-produced ones.

A guide was developed for highway agencies and the asphalt industry on sourcing and safely handling PCR plastics in dry-process RPM asphalt mixtures. While not an endorsement, it provides direction for future advancements. Ongoing research is needed to address remaining knowledge gaps.

Contact Fan Yin for more information about this research.