- Spring 2025

Benefits of Highly Modified Asphalt Mixtures

With increasing traffic volumes and limited budgets, DOTs face growing challenges to improve the durability and service life of asphalt pavements. One proven technology is high polymer content asphalt binders, commonly referred to as high polymer modified asphalt, or simply “HP binders”. Polymer suppliers may use other trademarked names, such as Kraton’s HiMATM technology.

What is High Polymer Modified Asphalt?

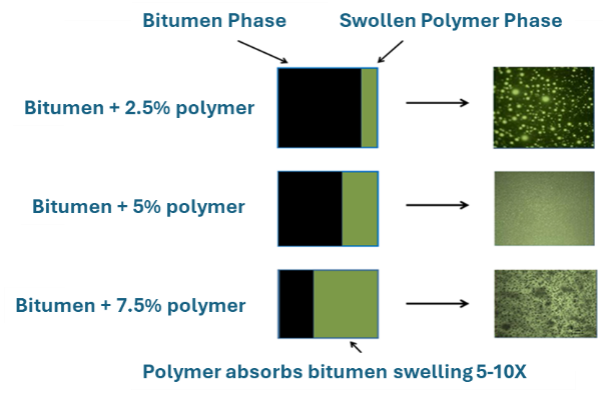

An HP mixture incorporates an asphalt binder modified with approximately 7% to 8% polymer, most commonly styrene-butadiene-styrene (SBS), which is more than twice the polymer content used in conventional polymer-modified binders (around 2 to 3 percent by weight). In traditional polymer-modified binders, the polymer exists as a dispersed swollen phase within the asphalt binder, enhancing its properties. However, when the polymer content is significantly increased, the binder structure transforms into a swollen polymer matrix with a dispersed asphalt phase. This structural shift results in a binder that exhibits rubber-like behavior, improving resistance to cracking and rutting, thereby enhancing overall pavement performance

Success Stories of Using HP Mixtures

Several field trials and research studies have demonstrated the effectiveness of HP mixtures in real-world applications. Notably, test sections constructed at the NCAT Test Track in 2009 have consistently shown superior resistance to rutting and cracking. DOTs in multiple states, such as Oklahoma, Florida, New York City, Virginia, Utah have successfully implemented HP in high-stress pavement locations, reporting extended service life and reduced maintenance costs. These success stories reinforce the value of HP mixtures in optimizing pavement performance and lifecycle costs.

Figure 1: Impact of increasing SBS polymer on binder/polymer morphology. (Source: FHWA-HIF-22-058)

Structural Layer Coefficient of HP Mixtures

To assess the structural benefits of HP mixtures, NCAT evaluated the structural layer coefficient using laboratory and field performance data from the Test Track sections constructed in 2009, 2010, and 2015. Four distinct methodologies were employed to compute the structural layer coefficient of HP mixtures:

- Effective Structural Number (SNeff) – Based on effective structural number calculated from Falling Weight Deflectometer (FWD) measurements.

- Modulus Correlation – Derived from FWD backcalculated modulus values.

- Equivalent Sections Approach – Combined in-situ strain measurements with laboratory bending beam fatigue test results.

- Performance-Based Calibration – Utilized field performance metrics, including applied traffic loading and measured International Roughness Index (IRI) values over time.

FWD-Dependent Methods (SNeff and Modulus Correlation), which rely solely on in-situ material properties from FWD testing, failed to differentiate between HP and conventional mixtures. This outcome was anticipated, as these methods inherently assume similar performance characteristics for asphalt concrete with equivalent modulus values.

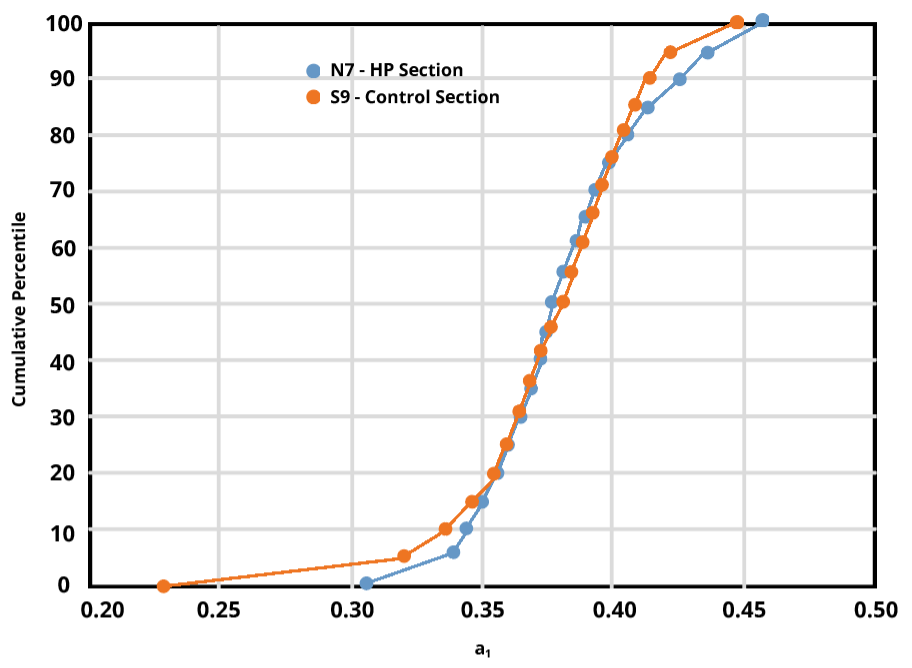

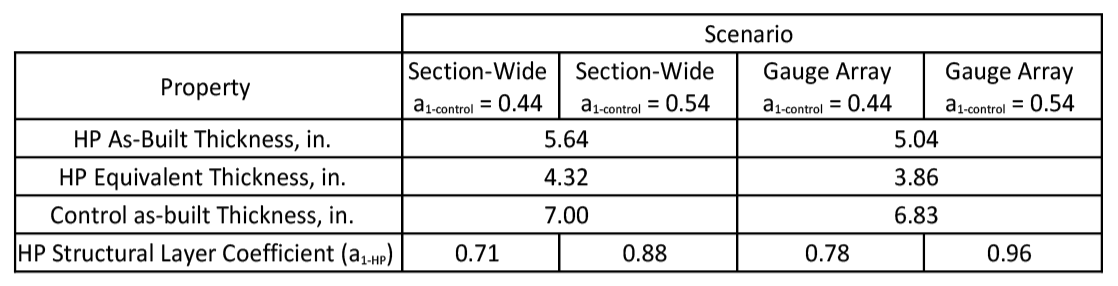

Equivalent Sections Approach using 2009 Test Track data successfully distinguished HP mixtures from conventional asphalt materials. The computed structural layer coefficients for HP mixtures ranged from 0.71 to 0.96, depending on data grouping and the assumed control layer coefficient (0.44 or 0.54). Based on this analysis, recommended structural layer coefficient values for HP mixtures were 0.75 and 0.92, compared to 0.54 and 0.44 for conventional mixtures, respectively.

The Performance-Based Approach using the 2010 sections yielded a structural layer coefficient of 0.92 for HP mixtures, aligning precisely with the Equivalent Sections Approach outcome when a control coefficient of 0.54 was assumed.

Figure 2: 2009 Test Sections a1 Cumulative Distributions from Effective Structural Number Analysis

Given the consistent results for the Equivalent Sections and performance-based approaches—both yielding a1-HP of 0.92—this value is recommended when conventional mixtures are assigned a structural layer coefficient of 0.54 (typical for unmodified or moderately polymer-modified binders). To be conservative, a value of 0.75 should be used if conventional materials are assigned a coefficient of 0.44.

Environmental Assessment of HP Sections

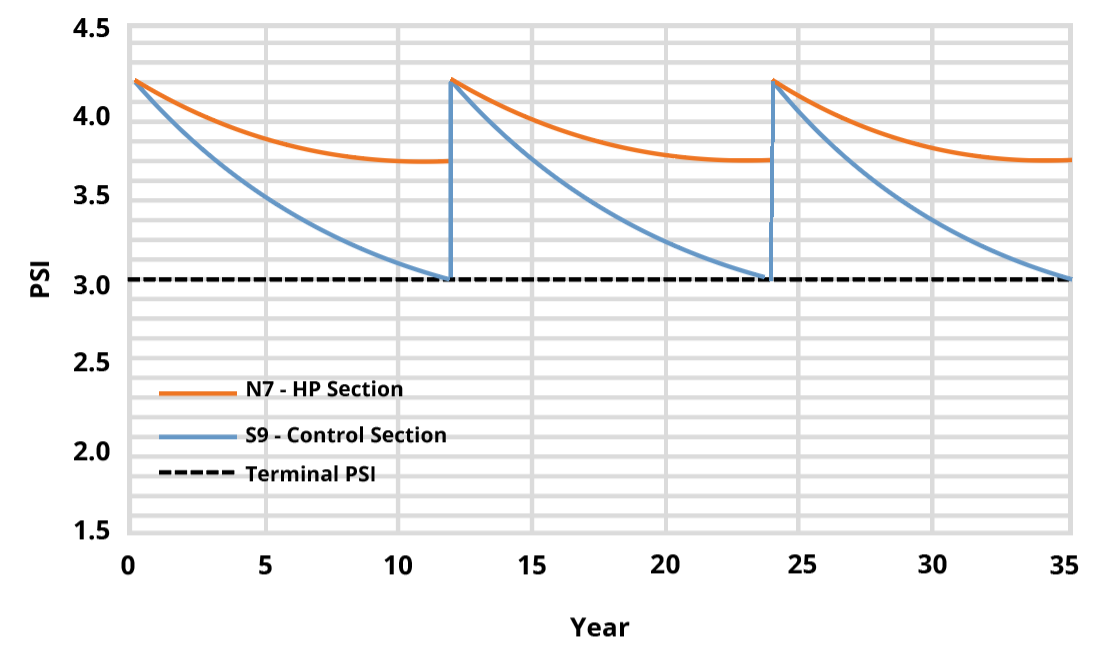

A comparative cradle-to-grave life cycle assessment (LCA) was performed between the HP section (N7) and the conventional section (S9) built at the Test Track to evaluate their long-term environmental impacts. Following ISO 14044 guidelines, the analysis used OpenLCA software and considered all lifecycle phases — including material production, construction, maintenance, and rehabilitation — over 35 years. The functional unit was defined as one lane-mile to standardize comparisons. The new recommended structural layer coefficient for HP mixture was used to predict the rate of deterioration of these two sections and determine future M&R activities over the life cycle. By extending the system boundary beyond initial construction to include future maintenance, this approach provided a comprehensive assessment of sustainability impacts across the pavement’s entire service life.

Table 1: 2009 HP Structural Layer Coefficients Computed from Equivalent Thicknesses

Figure 3: Performance Deterioration of Sections N7 and S9

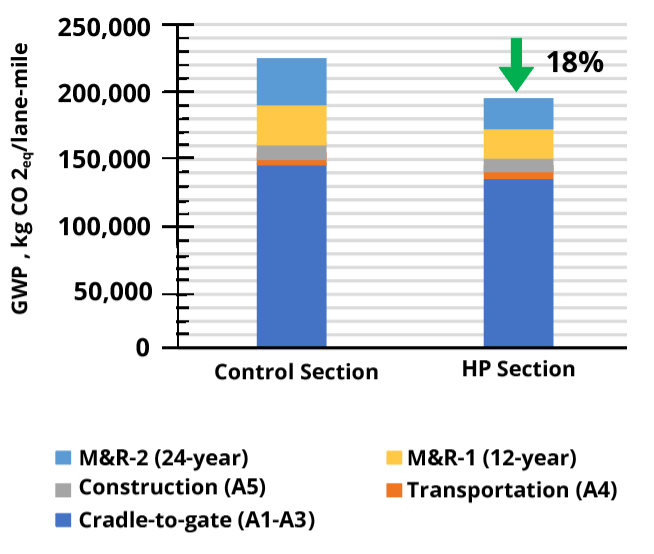

The initial construction phase (stages A1-A5) was found to be a major contributor to the cradle-to-grave greenhouse gas emissions. Future maintenance and rehabilitation activities (stages B2-B5) accounted for approximately 25-35% of the total global warming potential (GWP). This comparative analysis revealed that the HP section would have a 9% lower GWP than the control section in the as-built, cradle-to-constructed assessment. However, when considering the full lifecycle, including future maintenance and rehabilitation, this environmental advantage increased to 18%. The enhanced performance of the HP mixture – characterized by its higher structural number and superior durability – was primarily responsible for this additional reduction, as it eliminated the need for an overlay at years 12 and 24 of the analysis period.

Figure 4: Cradle-to-Grave Global Warming Potential (GWP) Impacts of Control and HP Sections

The results of the analysis support further use of HP mixtures, highlighting their performance and environmental benefits. As agencies and industries aim for sustainable and resilient infrastructure, HP mixtures stand out as a reliable technology for high-stress applications.

Contact Suri Gatiganti, Nam Tran, or Dave Timm for more information about this research.