- Spring 2025

Beyond Traditional Design: North Dakota validates balanced mix design to extend ND 14 pavement life

Optimizing asphalt mix designs is essential for enhancing pavement longevity and reducing lifecycle costs. North Dakota's Balanced Mix Design (BMD) Validation Project on Highway 14 (ND 14) seeks to provide practical insights for improving pavement performance in challenging climates.

A 21-mile section of ND 14, located approximately 20 miles east of Bismarck, has become a valuable real-world laboratory for the North Dakota Department of Transportation (NDDOT) as part of the BMD Validation Project. The reconstructed road, which experiences significant vehicle and truck traffic between I-94 and Canada, features eight distinct asphalt mix designs. These variations are intended to yield valuable insights into the durability of pavements under the state's harsh climate.

BMD uses performance testing to develop asphalt mixtures that resist multiple distress mechanisms, considering traffic, climate, and material aging. Unlike traditional volumetric methods, BMD optimizes mix performance by directly assessing resistance to rutting, cracking, and moisture damage.

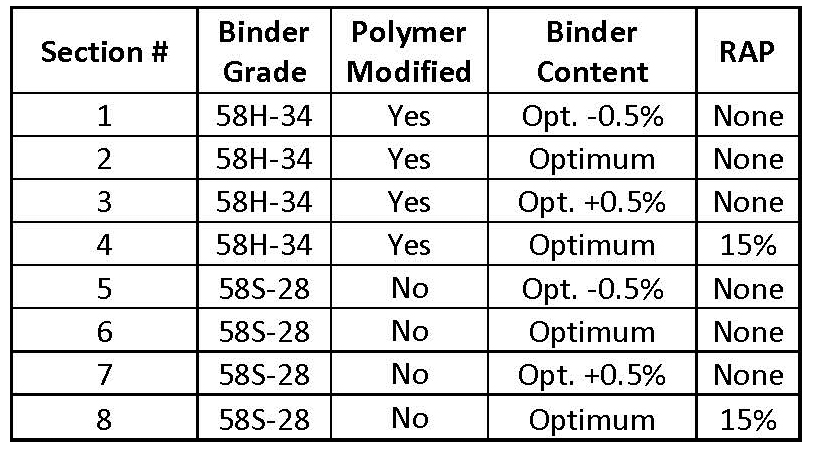

Constructed in the summer of 2024, ND 14 underwent significant structural changes, including a 10-inch full-depth reclamation and cement stabilization layer, topped by a Superpave asphalt layer beneath the test sections. NDDOT’s validation project features eight two-mile test sections in the top two inches of new asphalt, varying key design parameters, without using rejuvenators or additives. As shown in Table 1, two different grades of asphalt binder were used: PG 58S-28 and a softer PG 58H-34. The asphalt content was adjusted, ranging from 0.5% below optimum, at optimum, and 0.3% above optimum. Additionally, reclaimed asphalt pavement (RAP) was incorporated into two of the test sections.

Table 1. Validation Section Descriptions

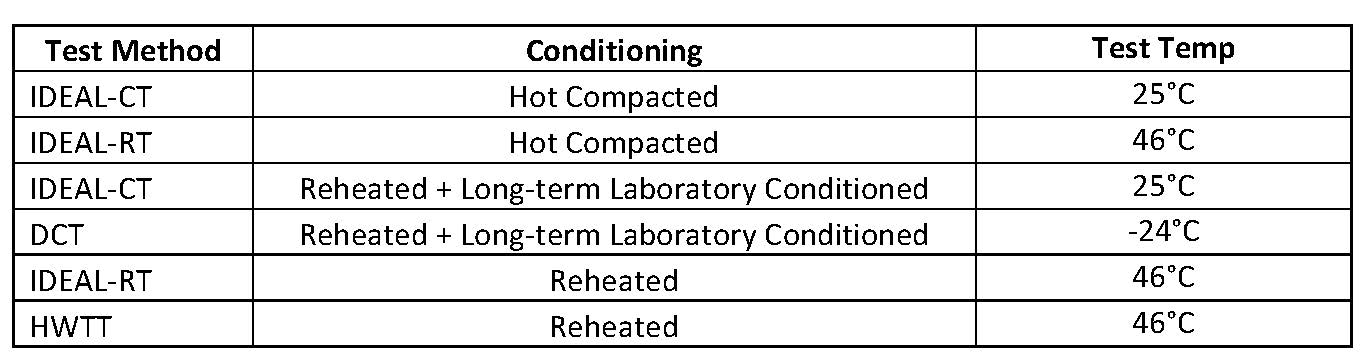

Laboratory testing by NDDOT and NCAT included the following assessments:

- Indirect Tensile Cracking Test (IDEAL-CT) to assess cracking resistance.

- Disk-Shaped Compact Tension (DCT) test to evaluate low-temperature cracking.

- Rapid Shear Rutting Test (IDEAL-RT) and Hamburg Wheel Tracking Test (HWTT) to measure rutting resistance.

North Dakota Highway 14 test section used to compare performance in the lab and on the road for BMD validation.

Mixes were tested under various conditioning states, including hot-compacted, reheated, and long-term conditioned for 20 hours at 110°C to simulate about eight years of field aging in ND. Table 2 shows more details of the laboratory testing plan.

Table 2. Laboratory Testing Plan

Initial laboratory testing has provided valuable insights into the performance characteristics of the different mix designs:

Intermediate-Temperature Cracking Resistance: The IDEAL-CT results showed reduced cracking resistance after simulated long-term aging. Higher asphalt content generally improved resistance to cracking, while the addition of RAP tended to reduce cracking resistance at optimal asphalt contents.

Low-Temperature Cracking Resistance: The DCT test results highlighted the importance of polymer modification in the binder for resistance to low-temperature cracking across varying asphalt contents. Mixes with unmodified binder showed more variability in low-temperature cracking resistance. Good low-temperature cracking resistance could still be achieved with slightly less than the optimum binder content in some cases.

Rutting Resistance: The IDEAL-RT test results showed a slight improvement in rutting resistance in reheated samples. Typically, higher binder content reduced rutting resistance, but RAP seemed to enhance it. Results from the HWTT confirmed that increased binder content led to lower rutting resistance, while polymer modification improved it. However, the effect of RAP on rutting resistance varied between modified and unmodified mixes; it decreased resistance in polymer-modified mixes but increased it in unmodified mixes. This contrasts with IDEAL-RT results, where RAP consistently improves rutting resistance. The discrepancy likely arises from the different loading mechanisms employed in the two rutting tests.

Biswajit Bairgi, NCAT post doctoral researcher, samples material from one of the test sections built to validate BMD test criteria.

NDDOT will monitor test sections over the next five years to compare lab and field performance under North Dakota’s traffic and climate. The findings will support the development of BMD specifications to improve pavement durability and resilience in future projects.

This ambitious project involves a collaborative effort with a diverse team of stakeholders, including material suppliers, paving contractors (such as Border States Paving, which undertook the ND 14 rebuilding), testing laboratories, NDDOT personnel, the Dakota Asphalt Pavement Association (DAPA), NCAT, and the Federal Highway Administration (FHWA).

Using ND 14 as a test section and field sites as variables, NDDOT is proactively working to optimize asphalt mix designs and ensure the longevity of its roadways for years to come. Findings from this project are expected to provide valuable guidance for other states facing similar pavement performance challenges in cold climates.

Contact Nam Tran or Zane Hartzog for more information about this research.