- Fall 2025

Spray-On Rejuvenators at MnROAD

If you manage pavements, spray-on rejuvenators are an appealing promise: a fast, easily applied treatment to buy time before the next overlay. But which products deliver, under what conditions, and with what tradeoffs?

To answer those questions, the National Road Research Alliance (NRRA) selected NCAT to lead the “Analysis of Long-Term Field Performance of Spray-On Rejuvenators” project, to turn two years of field results, chemical analyses, and rheology into actionable guidance. The goal was straightforward: quantify the short- and long-term effects of spray-applied rejuvenators on surface condition and safety, and on the properties of the binder within 3/8” of the pavement surface.

Study setup

In May 2021, MnROAD built two nearly identical asphalt pavement sections with the same dense-graded mix, including 20% RAP, but different binders: one with an unmodified PG 58S-28 and the other with a polymer-modified asphalt (PMA) PG 58H-34. Each section was divided into treated and control cells, and 12 spray-on rejuvenators (bio-based, petroleum-based, and one hybrid) were applied following each supplier’s instructions in July 2021. Products included in the study were voluntarily submitted and not selected or screened by MnDOT.

Testing approach

The study evaluated binder changes and pavement surface functional measures over 24 months. In the lab, recovered binders were assessed with SARA (saturates (S), aromatics (A), resins (R), and asphaltenes (A)) to assess colloidal stability, FTIR-ATR to track oxidation-related functional groups, and a suite of rheological metrics: PG, MSCR, and ΔTc, Glover-Rowe (G-R), and FAA P-632 parameters. In the field, the Dynamic Friction Tester (DFT), the Sand Patch, and the NCAT Asphalt Field Permeameter were used to investigate the impact of the treatments on surface friction, macrotexture, and permeability of pavement test sections following application.

This holistic evaluation was needed to evaluate how the spray-on rejuvenators altered binder properties, and more importantly, how they impacted the performance and safety of the riding surface.

1. Spray-on rejuvenator effectiveness is product-specific, not category-driven. The effectiveness of the 12 products did not sort neatly by bio- versus petroleum-based labels. Performance varied widely within each group, so approval by category is risky. Formulation quality, residual oil mass, and compatibility with the binder in the pavement surface were the real drivers of effectiveness.

2. Track application by the residual oil mass

(what actually stays with the pavement over time). The total application rate (gal/yd²) is needed for distributor control but has little relevance when comparing the performance of various products. Using residual oil mass

(lbs/yd²) helps explain binder and surface responses and offers a more meaningful quantification for specifications than spray rate. At the same time, excessive oil left on the surface can overly soften the binder, leading to friction loss and potential raveling. The takeaway: calibrate the residual oil mass to the pavement condition, surface texture, and permeability.

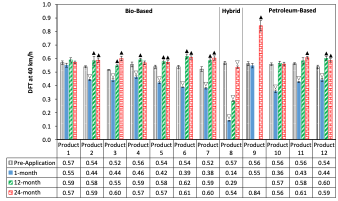

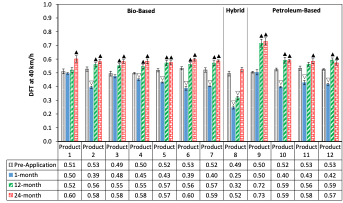

3. Expect early friction loss and plan accordingly. Most products reduced DFT at one month, then recovered by 12 months as materials cured (Figures 1 and 2, next page). The hybrid product showed the most persistent friction drop, while others rebounded near baseline by 12–24 months. Sections treated with the hybrid and petroleum-based products were sanded after application per supplier guidance to manage immediate friction loss. In short, make friction monitoring and mitigation (e.g., aggregate abraders) standard practice. Run short trial sections to avoid friction loss on impermeable surfaces and to fine-tune application rates and traffic-control timing based on the observed cure rates.

4. Chemistry and rheology together offer a fuller picture. Rejuvenated binders showed ΔTc and G-R improvements linked to reduced surface cracking, while FTIR/SARA results indicated better stabilization of oxidized molecules —suggesting longer pavement life. These changes in aged-asphalt properties are needed to justify spray-on rejuvenators, even if friction concerns require continued monitoring.

5. Binder type influences sensitivity to treatment. The unmodified binder (PG 58S-28) was more responsive to the spray-on rejuvenators than the PMA binder (PG 58H-34), which was less oxidatively aged to begin with. This suggests that binder type and aging level should inform product selection and timing strategies, as not all treatments are necessary or effective on polymer-modified pavements.

6. Product chemistry can confound chemical metrics. Some bio-based formulations distort SARA fractions because highly polar bio-oil molecules can co-precipitate with the asphaltene fraction. FTIR spectra targeting carbonyls to quantify aging are confounded when the natural carbonyls in the bio-oils are captured at similar FTIR wavelengths. Thus, the most beneficial molecules for binder stability and rheology are incorrectly characterized as more badly

aged asphalt.

7. Short-term softening is a confirmation step, not a gate. The FAA P-632 softening check (drop in |G*| at 60°C) reliably showed binder-rejuvenator interaction, but it did not predict 12 or 24-month outcomes in ΔTc or G-R. Several products that “failed” the softening threshold still performed well long term, so do not use softening in isolation for approval.

ATR-FTIR system with a diamond crystal.

Figure 1. DFT Results for Spray-on Rejuvenators – Base binder PG 58S-28.

Figure 2. DFT Results for Spray-on Rejuvenators – Base binder PG 58H-34.

How to use this on your next project

• Specify what stays on the pavement.

Make residual oil mass (lbs/yd²) the basis for dosage and for QA/acceptance. This provides a fair comparison across products with varying solvent or emulsion content and enables dosage calibration based on pavement absorption and condition. However, bio-oils have lower viscosities and lower densities than petroleum oils, so bio-oils should have the same rheological impact at lower application rates as determined by residual oil mass.

• Use two-stage acceptance. Do an early confirmation (30-45 days) on recovered surface binder properties and permeability tests, but base approvals on what matters most: 12-24-month trends in simple chemistry, binder behavior (ductility/brittleness rheology), and field friction/texture.

• Plan for safety (i.e., friction loss) from day one. Expect a short-term friction drop. Use temporary sanding, delayed traffic return, or application timing strategies to ensure safety during the early curing period.

• Match the product to the site. Choose a rejuvenator based on binder type

(PMA vs. unmodified), oxidation level, texture, and permeability. If in doubt, pilot on a small area first. Not all spray-on rejuvenators are suited for every pavement.

• Interpret chemical aging indices with awareness of solvent effects and FTIR procedural changes for bio-based materials. Avoid over-reliance on solvent-sensitive metrics (e.g., SARA fractions) during early post-treatment evaluations. Use complementary indicators such as FTIR oxidation or ΔTc for confirmation.

Application of a petroleum-based spray-on rejuvenator at the NCAT Test Track.

Bottom line

Spray-on rejuvenators can extend the life of a pavement surface, but success depends on matching the product and retained dose to the pavement and verifying performance over time. Focus specifications on residual oil mass, plan for early friction management, and evaluate chemical and rheological behavior together. With these steps, highway agencies can turn a promising treatment into a reliable preservation tool.

Contact Raquel Moraes for more information about this research.