- Fall 2025

Balanced RAP/RAS Mix Designs

What if the shingles that protect our homes could also be used to build durable pavements? The use of recycled asphalt shingles (RAS) in asphalt pavements has been around for decades, although the long-term results have been mixed. The initial economic benefits can be significant, as RAS reduces the demand for new raw materials. However, concerns about asphalt mixture durability, especially cracking resistance, have sidelined RAS in most states. Using a Balanced Mix Design (BMD) for mixtures containing RAS is recommended to ensure that the mixtures can resist both rutting and cracking, giving agencies confidence to incorporate RAS and other recycled materials without compromising performance.

To explore this potential, NCAT partnered with Owens Corning through its shingle recycling initiative, as well as with contractors in Oklahoma, Alabama, and Missouri for three case studies. These studies compared mixtures containing both reclaimed asphalt pavement (RAP) and RAS with control mixtures currently used in each state. Importantly, both mixtures in each comparison were optimized to meet the performance requirements outlined in each state's BMD special provisions. A life cycle assessment (LCA) was then conducted to evaluate the environmental impacts of the mixtures, which were expected to perform similarly in the field.

Case study approach and findings

Each case study followed the same overall approach. First, a RAP/RAS mixture was designed to have similar volumetric properties to a control mixture, which could be either a virgin mixture or a mixture containing RAP, depending on the specific state. The resistance of both mixtures to rutting and cracking was then evaluated.

Next, both mixtures were optimized to meet the specific BMD requirements of each state. This optimization involved adjusting, such as using softer or modified binders, incorporating recycling agents, or changing the binder content. The laboratory cracking and rutting resistance of the optimized RAP/RAS mixtures was compared to that of the control mixtures. Additionally, a cradle-to-gate life cycle assessment (LCA) was conducted to evaluate their environmental impacts.

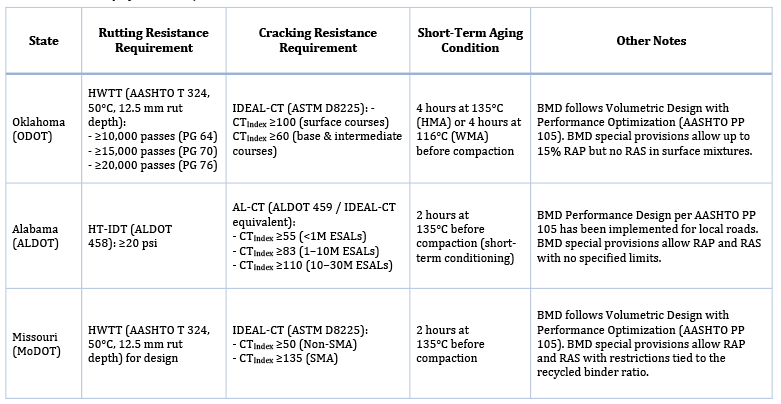

Table 1: Summary of BMD Requirements in Three Case Studies.

BMD test results

The initial volumetric mix designs for both the control and RAP/RAS mixtures did not meet the BMD requirements (Table 1) in any of the three case studies. Each mixture failed cracking or rutting requirements, requiring state-specific modifications based on materials and specs.

• Oklahoma: The virgin control mixture with a PG 64-22 binder required an additional 0.35% binder to pass the BMD requirements. The RAP/RAS mixture (7% RAP, 2% RAS) achieved balanced performance after a series of modifications, including the use of a softer PG 58-28 binder, an addition of 0.5% liquid antistrip (LAS) agent, and a 0.3% increase in binder content.

• Alabama: The 20% RAP control mixture with a PG 67-22 binder met BMD requirements after adding 0.3% binder. The RAP/RAS mixture (15% RAP, 5% RAS) achieved balanced performance through

two alternative strategies: (1) using a softer PG

52-28 binder with an additional 0.5% binder, or

(2) incorporating a recycling agent dosed at 7.8% of the virgin binder.

• Missouri: The 30% RAP control mixture with PG 64-22H required a stiffer PG 64-22V grade to meet rutting/cracking tests, while the RAP/RAS mixture (15% RAP, 3% RAS) mix met BMD by reducing binder 0.3% and adding 0.5% LAS.

These changes ensure that the mixtures comply with the necessary BMD criteria across different states.

Life cycle assessment results

Life cycle assessments conducted on the three case studies highlighted the significant impact of binder type and content on environmental outcomes.

• Oklahoma: The RAP and RAS mixture reduced most impact categories by up to 5% compared to the virgin control, which included a 4.8% decrease in global warming potential (GWP).

• Alabama: Under volumetric design, the RAP/RAS mixture also reduced impacts by up to 5%, with a 2.6% decrease in GWP. After BMD optimization, results varied: a softer binder gave minimal gains, while a recycling agent reduced virgin binder needs but added offsetting burdens.

• Missouri: The RAP/RAS mixture initially showed slightly higher impacts than the control under volumetric design. After BMD optimization, however, it reduced impacts by up to 8%, including a 4.8% reduction in GWP.

Overall, RAP/RAS mixtures designed to meet BMD requirements reduced GWP by nearly 5% (equivalent to 2–3 kg CO₂e per ton of mix) in two of the three cases, demonstrating their potential to achieve both performance and responsible resource use.

Summary

These case studies illustrate that with careful design under the BMD framework, RAP/RAS mixtures can deliver performance test results comparable to control virgin or RAP-only mixtures while promoting the responsible use of resources. In the Oklahoma, Alabama, and Missouri case studies, RAP/RAS mixtures reduced global warming potential by approximately 2–3 kg CO₂e per ton (about 5%) when both mixtures were designed to meet state BMD requirements.

Three key lessons emerge from this analysis:

• To meet the BMD requirements, adjustments may be necessary for volumetric mix designs, particularly those incorporating both RAP and RAS. While these mixes may not perform well under BMD testing, they can still satisfy rutting and cracking criteria. Possible adjustments include using softer binders, adding recycling agents, or modifying binder contents.

• Reducing the virgin binder content by 0.3–0.5% can significantly impact LCA results; however, certain additives may offset these benefits if they are required for specific mixtures.

• The benefits of using RAP and RAS mixtures can vary based on differences in materials and specifications. In Oklahoma, RAP/RAS mixtures demonstrate notable resource efficiency compared to virgin mixtures. However, the comparative benefits are more complex when analyzed against RAP-only controls in Alabama and Missouri.

Overall, these findings demonstrate that RAP/RAS mixtures can contribute to the development of durable pavements while supporting the responsible use of resources.

Contact Nam Tran for more information about this research.