- Fall 2025

Does IDEAL-RT Correlate with HWTT for Rutting Evaluation of Asphalt Mixtures?

The Hamburg Wheel Tracking Test (HWTT, AASHTO T 324) is widely used by state highway agencies to evaluate the rutting resistance of asphalt mixtures. Since the test is conducted with the specimens submerged in water, it can also be used to assess moisture resistance. A typical HWTT test takes up to eight hours, including temperature conditioning and testing. This extended timeframe poses a challenge for production testing, where quick turnaround of test results is important for timely quality control and acceptance decisions. The Indirect Tensile Asphalt Rutting Test (IDEAL-RT, ASTM D 8360) has recently been considered as an alternative method to HWTT for evaluating rutting resistance during production. Although many studies report a correlation between these two tests, discrepancies remain for certain asphalt mixtures due to undetermined reasons. Additionally, many studies are constrained by a limited number of mixtures and insufficient variation in material components across the evaluated mixtures, which undermines the reliability of the correlation due to a narrow spread in test results.

Building a broader dataset

To address these knowledge gaps, NCAT researchers compiled a comprehensive database incorporating HWTT and IDEAL-RT results for 68 asphalt mixtures sourced from the southeast, midwest, and northeast regions of the United States. All mixtures are dense-graded except for two gap-graded stone matrix

asphalt (SMA) mixtures. Of these, 60 are plant-produced mixtures, and the rest are

laboratory-prepared mixtures.

Each mixture was evaluated for rutting resistance using both HWTT and IDEAL-RT. HWTT was conducted at 45°C, 46°C, or 50°C, according to the respective agency’s requirements. IDEAL-RT was conducted at the same temperature as the HWTT. The evaluated mixtures exhibit a wide range of rutting resistance, as indicated by the HWTT rut depth ranging from 1.1 mm at 20,000 passes to 12.5 mm at 6,700 passes and the rutting tolerance index (RTIndex) varying from 38 to 174.

The HWTT results were analyzed using the total rut depth at 20,000 passes (TRD20k) and the number of passes to 12.5 mm rut depth (N12.5), as specified in AASHTO T 324, along with the rutting resistance index (RRI) and the corrected rut depth at 20,000 passes (CRD20k), as recommended in recent literature. TRD is only applicable to mixtures where the test was terminated at 20,000 passes with less than

12.5 mm rut depth, while N12.5 only applies to mixtures where the test was terminated upon reaching 12.5 mm rut depth before 20,000 passes. RRI serves as a combined parameter for TRD and N12.5, calculated using Equation 1. It enables direct comparison among mixtures regardless of the test termination criterion. Higher RRI values indicate better rutting resistance.

RRI = Nmax x (1 – RDmax)

Understanding corrected rut depth (CRD)

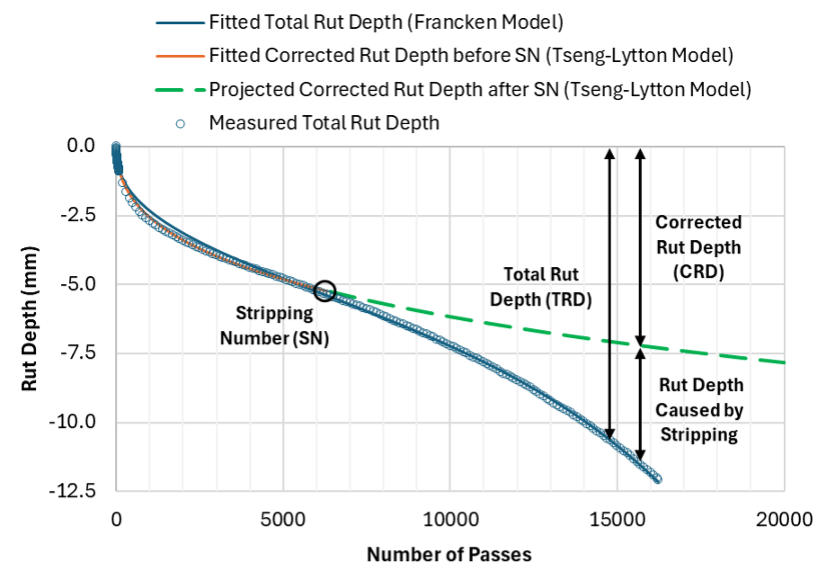

CRD represents the rut depth caused by the post-compaction and permanent deformation of the mixture, excluding the rut depth due to stripping. Calculation of CRD involves fitting the rut depth data to the Francken model to identify the inflection point, referred to as the stripping number (SN), then

applying the Tseng-Lytton model to the data

preceding this point.

After determining the model coefficients, the

Tseng-Lytton model may provide the projected

CRD beyond SN.

Figure 1 provides a graphical illustration of CRD determination. Lower CRD values are desired for asphalt mixtures with better rutting resistance. These values offer a more accurate reflection of a mixture’s true structural performance by isolating deformation from moisture-related damage. As such, CRD is a valuable parameter for comparing rutting potential across mixtures with varying susceptibility to stripping.

Figure 1. Determination of the HWTT CRD Parameter.

Comparing correlation results

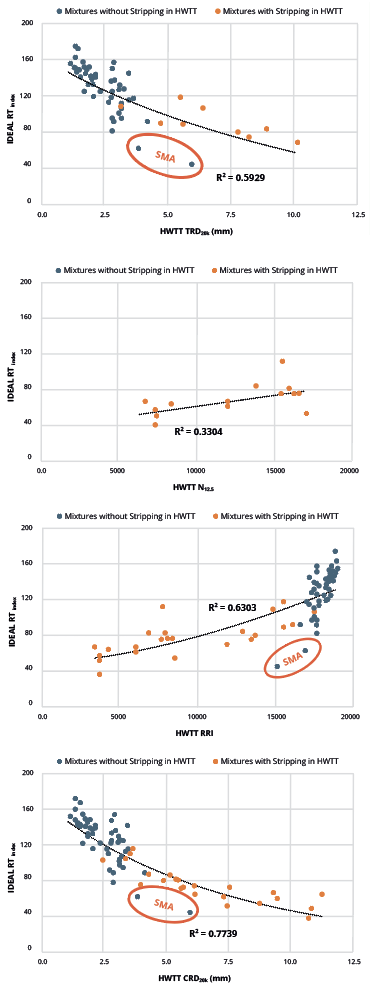

Figure 2 shows the correlation between RTIndex and HWTT parameters, grouped by mixtures with and without stripping. RTIndex has the strongest correlation with CRD20k, followed by RRI, TRD20k, and N12.5. The strong correlation between RTIndex and CRD20k is due to both being pure rutting parameters, making this relationship valid across all mixtures regardless of stripping. In contrast, RRI, TRD20k, and N12.5 reflect both rutting and moisture resistance, which may weaken their correlation with RTIndex due to the effects

of stripping.

The data also show that HWTT classifies the two SMA mixtures as highly rutting-resistant, based on low TRD20k and CRD20k values and high RRI. However, IDEAL-RT indicates these same mixtures may be prone to rutting, shown by their low RTIndex values. Given SMA’s strong field performance, this suggests IDEAL-RT may not be suitable for SMA evaluation, likely due to the lack of confinement needed for stone-to-stone contact.

Figure 2. IDEAL-RT and HWTT Correlation Results:

(a) RTIndex versus TRD20k, (b) RTIndex versus N12.5,

(c) RTIndex versus RRI, (d) RTIndex versus CRD20k

Key takeaways

To answer the question, “does IDEAL-RT correlate with HWTT for rutting evaluation of asphalt mixtures?”, the correlation between these two tests is highly dependent on the specific HWTT parameters used. RTIndex has a strong correlation with CRD20k as a pure rutting parameter, and this relationship appears applicable across mixtures with different component materials and test temperatures, as well as those with distinctly different rutting and moisture resistance. In contrast, RRI, TRD20k, and N12.5 exhibit weaker correlations with RTIndex than CRD20k, due to the confounding influence of stripping. Therefore, these parameters should be used with caution when correlating to RTIndex for rutting evaluation of asphalt mixtures, especially those subject to stripping failures during HWTT.

Contact Fan Yin for more information about this research.