- Fall 2025

Standardization of SIP Calculation Method for the Hamburg Wheel Tracking Test

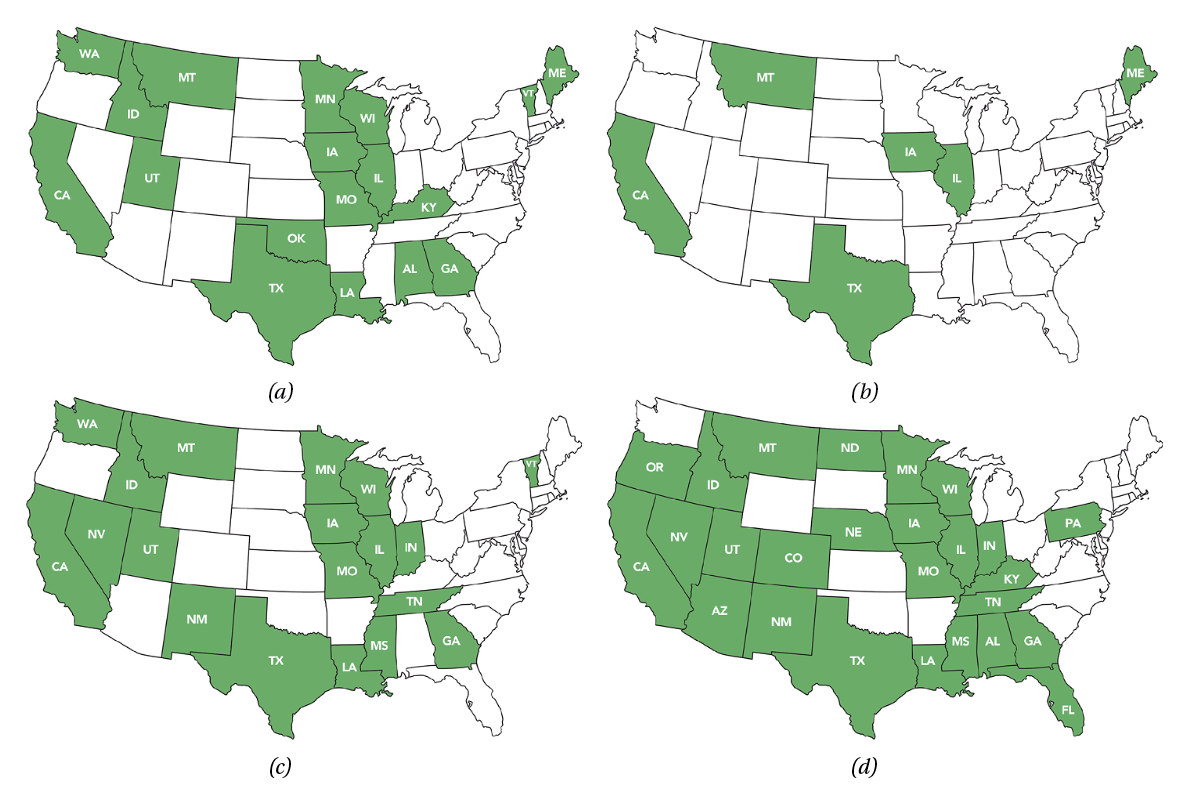

A 2024 survey of state DOTs found that 32 agencies use the Hamburg Wheel Tracking Test (HWTT) to evaluate asphalt mixtures for rutting and/or moisture resistance. Of those DOTs, 18 use it for mix design approval, six for production acceptance, 19 for forensic analysis, and 26 for research evaluation, as shown in Figure 1. While test temperatures and criteria vary among these agencies, stripping inflection point (SIP) is the most commonly used parameter for evaluating moisture susceptibility.

Figure 1. State DOTs using HWTT for (a) Mix Design Approval, (b) Production Acceptance, (c) Forensic Analysis, and(d) Research Evaluation.

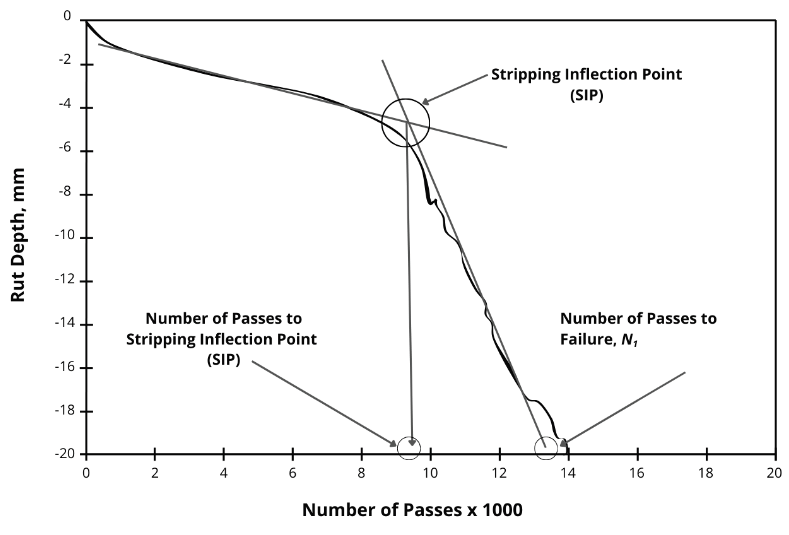

According to AASHTO T 324-23, SIP is graphically identified as the intersection point of the first and second steady-state portions of the rut depth curve, as illustrated in Figure 2 (next page). However, the standard does not provide explicit guidance on defining these steady-state portions. As a result, HWTT equipment manufacturers and asphalt practitioners have developed different methods, which often result in different SIP results.

The survey found that of 17 DOTs using SIP, only two prescribe a specific calculation method, while the other 15 rely on manufacturer-reported values — leading to possible discrepancies in SIP results for the same HWTT data.

In 2024, the National Road Research Alliance (NRRA) awarded a research project to NCAT to address

this issue1.

Figure 2. Graphical Illustration of SIP Determination in AASHTO T 324-23.

Research objectives to standardize SIP

The project has two objectives: standardize the SIP calculation method and develop software for automating the calculation of SIP and other test parameters using direct output files from selected HWTT equipment. A comprehensive literature review identified seven distinct SIP calculation methods used by equipment manufacturers, state DOTs, and asphalt researchers. Each method was reviewed for pros and cons, and the most robust was recommended for SIP standardization.

The recommended method involves fitting the Franken model to the rut depth data, as shown in Equation 1, followed by determining the inflection point of the fitted curve. The tangent at the inflection point defines the creep line, the endpoint tangent defines the stripping line, and SIP is the passes at their intersection. If the fitted rut depth curve lacks an inflection point, the mixture is assumed free of stripping damage and SIP is not calculated.

RD = ANB + C (eDN – 1)

Where, RD = rut depth; N = number of passes; and

A, B, C, and D are model coefficients.

Finally, a web-based software, HWTTXpert, was developed to automate the calculation of SIP and other testing parameters specified in AASHTO T 324-23, such as the maximum rut depth, corresponding number of passes, creep slope, and stripping slope. The software also provides two additional parameters recommended in research at NCAT and the Texas A&M Transportation Institute: the corrected rut depth (CRD) and the stripping number (SN)2,3. Compared to traditional parameters, CRD and SN offer improved evaluation of rutting resistance and moisture susceptibility, respectively, as they minimize confounding effects between

these distresses.

Validation and public release

Following its initial development, HWTTXpert underwent alpha testing at NCAT and with three HWTT equipment manufacturers (InstroTek, Inc., Pavement Technology, Inc., and Troxler Electronic Labs, Inc.), followed by beta testing with 12 state DOTs. Based on feedback received, the software was finalized and is scheduled for public release in October 2025.

Interested parties may register by clicking here to receive login credentials, the user manual, and future software updates.

Sources

1 Yin, F., Chen, C., and Li, Q. (2025). Standardization of SIP Calculation for Hamburg Wheel Tracking Test. NRRA Flexible Team Research Project (https://www.dot.state.mn.us/mnroad/nrra/structure-teams/flexible/standardization-sip-hwtt.html), Final Report.

2 Yin, F., Arambula, E., Lytton, R., Martin, A.E. and Cucalon, L.G. (2014). Novel method for moisture susceptibility and rutting evaluation using Hamburg wheel tracking test. Transportation Research Record, 2446(1), pp.1-7.

3 Yin, F., Chen, C., West, R., Martin, A. E., and Arambula-Mercado, E. (2020). Determining the relationship among Hamburg wheel-tracking test parameters and correlation to field performance of asphalt pavements. Transportation Research Record, 2674(4), 281-291.

Contact Fan Yin for more information about this article.