- Fall 2019

Refining the Ignition Method for Asphalt Content Determination

Developed at NCAT, the ignition oven set the industry standard for determining asphalt content by ignition method.

Accurate determination of asphalt content and aggregate gradation is critical for controlling the quality of asphalt mixtures during construction. Most state specifications require quantitative evaluation of the asphalt content as a criterion for acceptance. The ignition method detailed in AASHTO T 308 is required or allowed by most state DOTs for determining the asphalt content of a mixture.

Developed in the mid-1990s, the procedure was rapidly implemented by laboratories to eliminate the use of hazardous solvents needed for extraction methods. The ignition method removes the binder from mixture samples by burning the binder at a high temperature, typically 1000°F. The test is complete when the change in mass does not change by more than 0.01% for three consecutive minutes. AASHTO T 308 includes two procedures, one for furnaces with an internal balance and one for furnaces without an internal balance.

Since the extremely high temperature used in the test also results in some loss in aggregate mass, the determination of an asphalt content correction factor (CF) is required for each mix and each ignition oven used. Developing the CF involves the preparation of two samples of the asphalt mixture at the design asphalt content. The CF samples are tested and the CF is calculated as the difference between the actual and measured asphalt binder contents expressed as a percentage of the total mix mass.

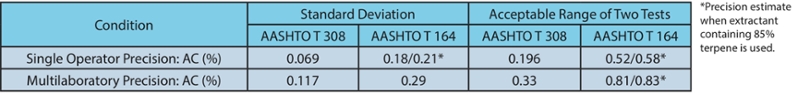

As shown in Table 1, the precision of the ignition method is much better than the solvent extraction method detailed in AASHTO T 164. The acceptable range of ignition method results for split samples tested in different labs is less than half of the acceptable range of the solvent extraction test.

Table 1. AASHTO T 308 and AASHTO T 164 - Precision Statements

Although the ignition method is straightforward and more precise than solvent extraction, there are still issues that need to be improved. Some agencies and/or contractors share CFs between ignition units. For example, it is common to determine a CF during mix design and then use that same CF for other furnaces during quality control testing, acceptance testing, and/or independent assurance testing of the mixture. Although this can significantly reduce the test time when more than one unit is being utilized, this approach violates AASHTO T 308, which states that a CF should be established for each mix and for each ignition test unit. Another issue for some regions of the country is with aggregates that have relatively high and/or inconsistent CFs. For example, dolomites are known to undergo chemical changes at high temperatures, causing some decomposition and a higher mass loss than other common aggregate types.

NCHRP 9-56 was funded to explore solutions to these problems. The research, conducted by NCAT, included a survey of state DOTs and asphalt contractors regarding practices used with the ignition method and experiments to determine the sensitivity of the method with respect to aggregate type, furnace type, test temperature, asphalt content, and sample mass. The project also included an interlaboratory study to assess the precision of ignition method CFs for different mixes.

The information requested in the survey included furnace types, typical ranges of asphalt content CFs, aggregate types, and possible factors affecting CFs. Survey results showed that the most common unit was the Thermolyne convection furnace, followed by the Troxler infrared unit, both with internal balances. Very few labs use the Gilson furnaces with no internal balances. The majority of respondents indicated that their CFs were less than 1.0%. The respondents also indicated that aggregate geology, test temperature, and inclusion of hydrated lime may affect CFs.

The sensitivity and interlaboratory studies included four asphalt mixtures using three aggregate blends, and one blend was prepared with and without hydrated lime. The aggregate types were selected based on their historical CFs. Mix 1 had a CF less than 0.5, Mix 2 had the same aggregate blend as Mix 1 except it contained 1.0% hydrated lime, Mix 3 used aggregates that had a CF between 0.5-1.0, and Mix 4 used aggregates with a CF greater than 1.0.

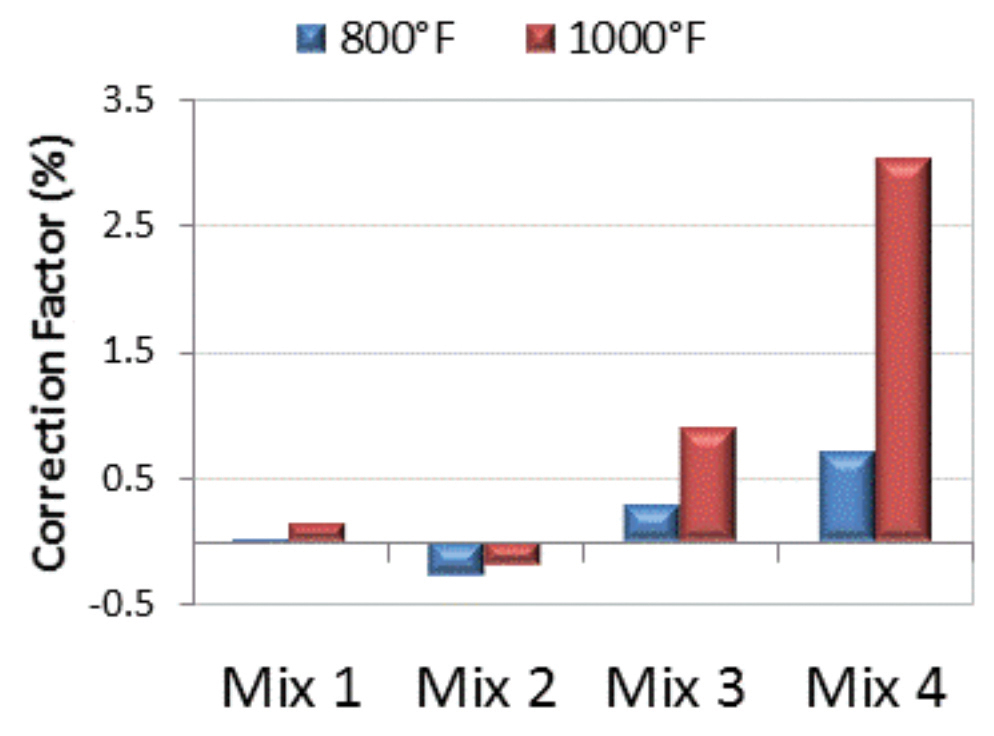

The results of the sensitivity study showed that test temperature was the primary factor affecting the asphalt CF. From Figure 1, it is evident that decreasing the test temperature from 1000°F to 800°F decreased the aggregate mass loss for all mixes that didn't contain lime. It is interesting to note that for the mix containing hydrated lime, the mass gain at 800°F was lower than for the tests at 1000°F. Also, the tests at 800°F effectively removed all of the binder from the mixes without substantial changes in testing time.

Figure 1. Asphalt Content CFs at Different Test Temperatures

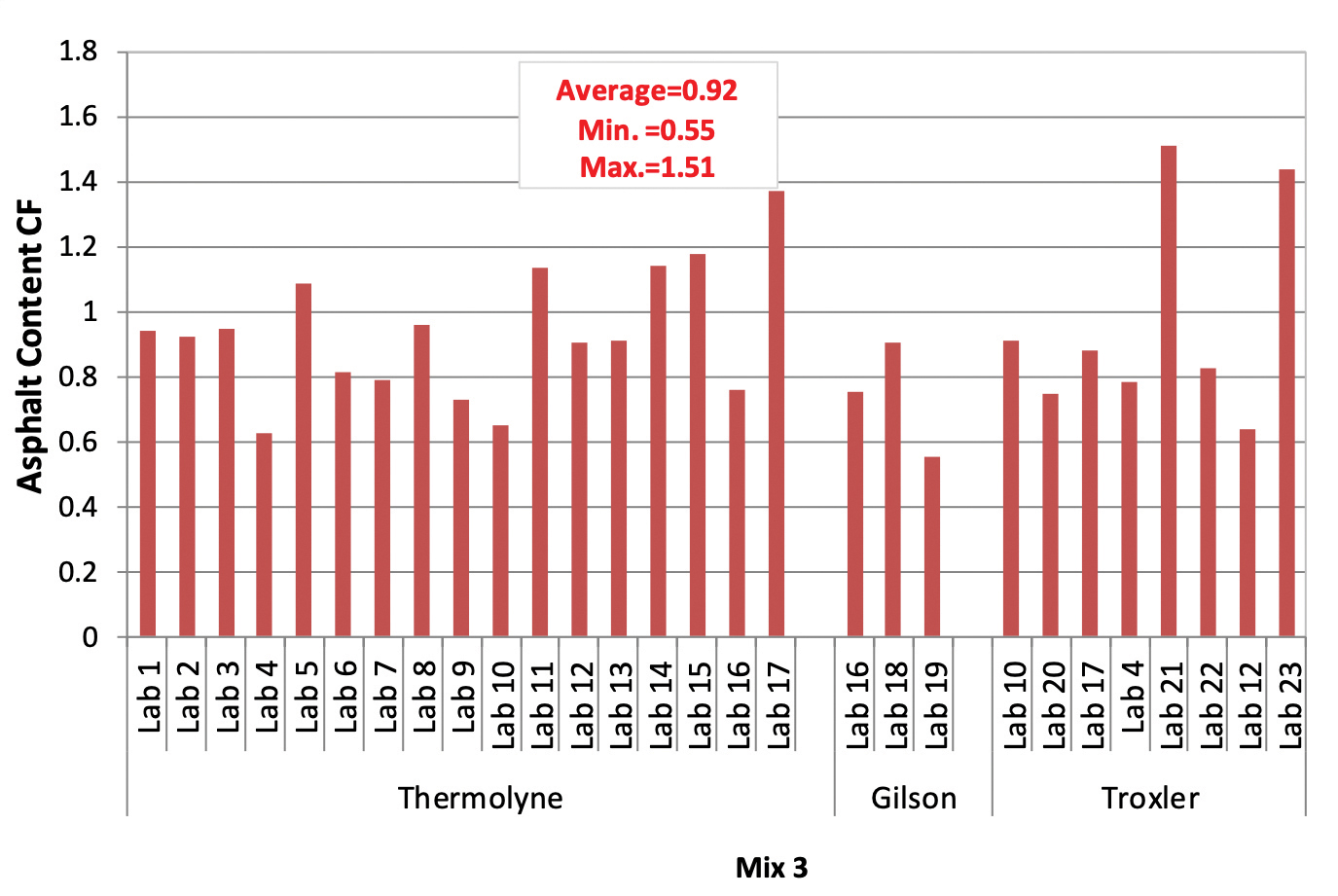

Twenty-three labs participated in an interlaboratory study to evaluate test precision. Each of the three brands of ignition furnace were represented in the experiment. Tests were conducted with the furnace set to 1000°F for Mixes 1, 2 and 3, and at 900°F for Mix 4 (as currently recommended in the AASHTO procedure for high mass aggregates). Figure 2 shows the average asphalt CFs for Mix 3 for each laboratory. The minimum and maximum CFs are also reported and the information is grouped by unit type. The results indicate that even when ovens of the same brand are used, the CFs vary significantly. Similar results were obtained for the other three mixes.

Figure 2. Asphalt Content Average Correction Factors - Mix 3

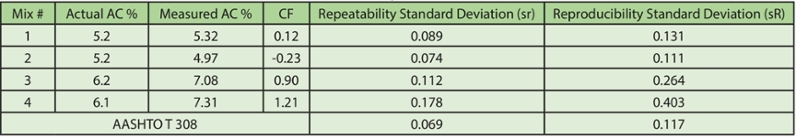

Table 2 summarizes the average asphalt content, average CF, and within- and between-lab standard deviations for each mix. Mixes 1 and 2 had similar within- and between-lab standard deviations: 0.089 and 0.074 for within-labs and 0.131 and 0.111 for between-labs. These results are close to the repeatability and reproducibility standard deviations in AASHTO T 308: 0.069 and 0.117, respectively. The results in Table 2 show that as the CFs increased (Mixes 3 and 4) the standard deviations increased. The within-lab standard deviations for Mixes 3 and 4 were 0.112 and 0.178, respectively, and the between-lab standard deviations were 0.264 and 0.403, respectively.

Table 2. Precision Statement Comparison for Asphalt Binder Content by Mix

It is also evident in Table 2 that the addition of hydrated lime caused a significant change in the CF, from 0.12 with no lime to -0.23 with 1% lime, a difference of 0.35. The effect of hydrated lime has been reported in other studies. Prowell and Youtcheff 1 explained that during the test, CaO from the lime reacts with oxygen in the furnace and sulfur present in asphalt binders at varying percentages, depending on crude source, to form CaSO 4 (anhydrite) in the ash. Stoichiometrically, this reaction product could increase ash mass by 4.53 times the sulfur content of the asphalt, and therefore, result in a negative CF.

This study concluded that CFs were significantly different for different mixes even when the same brand of furnace was used. This means that it is not appropriate to use the CF for a mix determined with one ignition furnace for tests conducted on the mixture with another furnace. The study also found that the within-lab and between-lab precision information depend on the magnitude of the CF. Mixtures with high CFs have poorer repeatability and reproducibility.

As part of this study, a Standard Practice for Installation, Operation, and Maintenance of Ignition Furnaces was proposed and published as AASHTO Standard R 96-19.

Although this study did not include any mixes with RAP, it is expected that conducting ignition tests at 800°F would improve the accuracy of determining the asphalt content of RAP materials. A follow-up study is currently underway to assess the variability of asphalt CFs for mixes containing recycled materials. In addition, the effect of reducing the test temperature to 800°F is under evaluation. For the final task of this project, another interlaboratory study will be conducted to establish a new precision statement for AASHTO T 308. This interlaboratory study will include virgin and recycled asphalt mixes.

For more information about this article, please contact Carolina Rodezno.

1Prowell, B. D., and J. Youtcheff. Effect of Lime on Ignition Furnace Calibration. Transportation Research Record: Journal of the Transportation Research Board, No. 1712, TRB, National Research Council, Washington, D.C., 2000, pp. 74-78.