- Fall 2021

Optimizing Recycled Materials Contents by Using Recycling Agents

Using reclaimed asphalt pavements (RAP) and recycled asphalt shingles (RAS) in asphalt mixtures can provide materials cost savings, conserve natural resources, and reduce energy consumption and associated greenhouse gas emissions. Although increasing the amount of these materials used in an asphalt mixture typically increases rutting resistance, it can also increase its susceptibility to cracking and may cause durability issues if the mix design does not adequately account for the aged binder in the recycled materials.

NCAT recently completed a study for the Wisconsin Highway Research Program with the following objectives: (a) evaluate how the quantity and quality of recycled materials affect the performance of binder blends; (b) validate binder results with mixture testing, and (c) draft a procedure to evaluate the quality of asphalt blends with high recycled contents and guide the use of recycling agents (RAs) to produce recycled asphalt mixtures with optimized performance.

The Wisconsin Department of Transportation (WisDOT) currently allows up to 40% asphalt binder replacement (ABR) for lower pavement layers and 25% in upper layers. ABR is defined as the percentage of the recycled binder in the total binder (virgin + RAP &/or RAS binder).

The first part of the study evaluated the rheological and chemical properties of several asphalt binder blends with a range of recycled materials contents and additives [i.e., polymer, and petroleum- and bio-based RAs]. Testing included Superpave performance grading (PG), linear amplitude sweep (LAS), gel permeation chromatography (GPC), and other tests.

Binder results were validated through performance testing of asphalt mixtures. Mixtures were tested for rutting resistance with the Hamburg wheel tracking test (HWTT) after short-term oven aging (STOA) for four hours at 135°C. The indirect tensile asphalt cracking test (IDEAL-CT) was used to evaluate intermediate-temperature cracking resistance and the disc-shaped compact tension test (DCT) was used to evaluate low-temperature cracking resistance after being subjected to STOA plus long-term oven aging (LTOA) of six hours at 135°C. In addition, the dynamic modulus (|E*|) test was conducted at both STOA and LTOA conditions to assess the stiffness characteristics and aging resistance of the mixes.

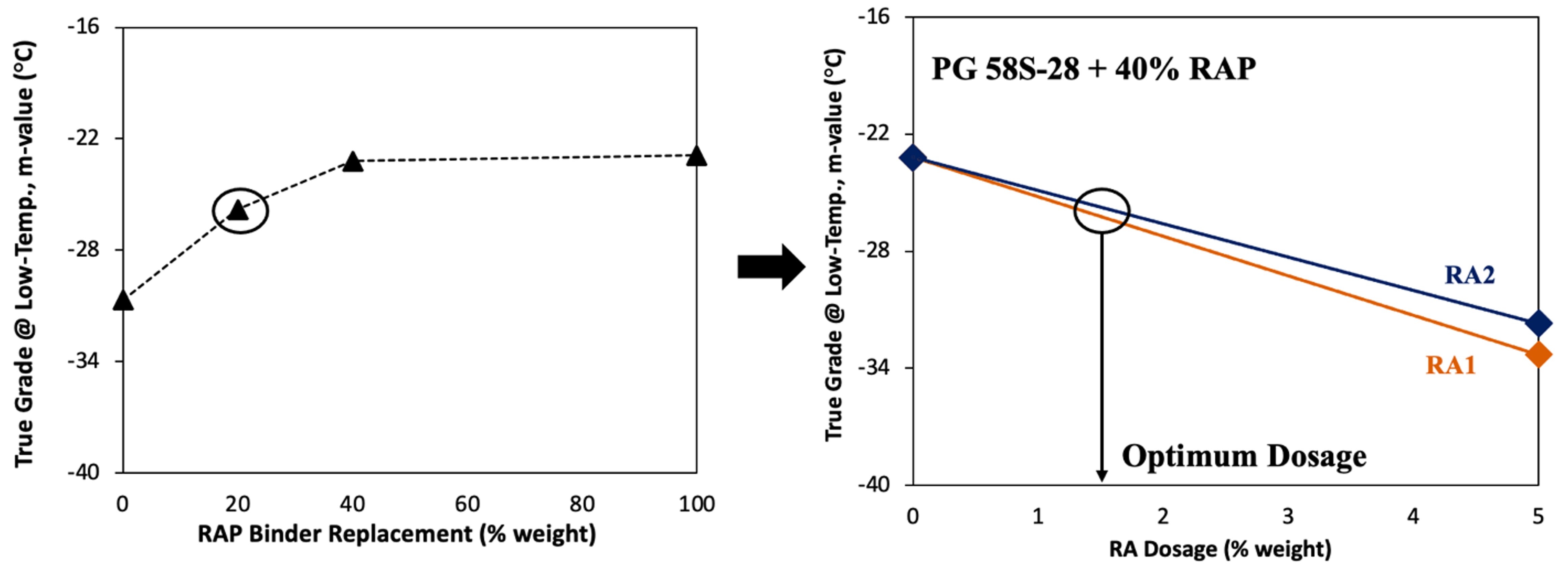

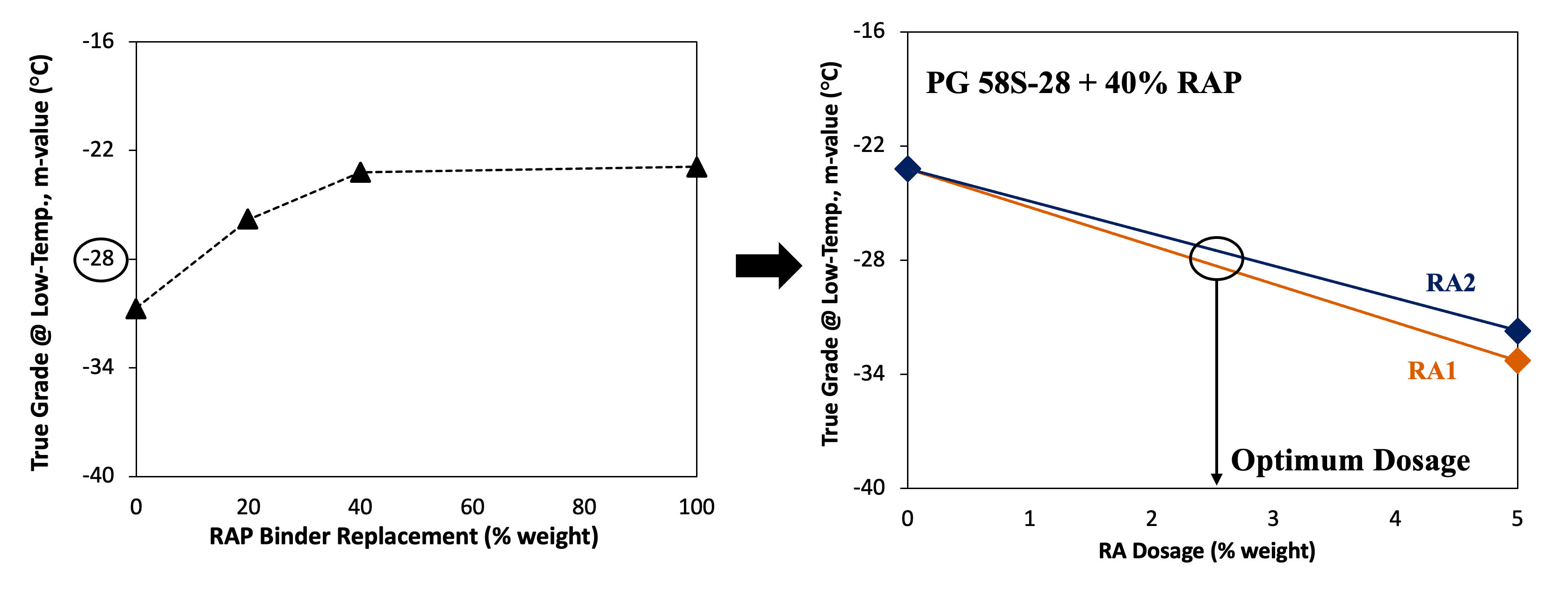

Optimum dosages for the RAs were determined using blending charts based on dynamic shear rheometer (DSR) and bending beam rheometer (BBR) test results. In this analysis, the critical high-temperature and low-temperature of a recycled binder blend is plotted against the tested RA dosage. For bio-based RAs, an initial dosage of 5% by weight of total binder (i.e., virgin plus recycled binders) was used, while an initial dosage of 20% by weight of total binder was utilized for a petroleum-based (i.e., asphalt flux) RA. Several approaches for determining the optimum dosage determination of each RA were evaluated. The approaches are illustrated here:

- Approach 1a: Target a “20% RAP-BR” high-temperature grade of DOT control blend

- Approach 1b: Target a “20% RAP-BR” low-temperature grade of DOT control blend (Figure 1)

- Approach 2: Target a “PG xx-28” grade (i.e., match the low-temperature grade for Wisconsin climate) (Figure 2).

Approach 1a resulted in the highest RA dosage among all of the evaluated approaches. Although this approach was recommended in NCHRP Project 9-58, the researchers warned of a potential increase in moisture susceptibility of asphalt mixtures when this approach is used. Approach 1b resulted in the lowest RA dosage among the evaluated approaches. NCHRP Project 09-58 reported that this approach was insufficient to yield acceptable cracking resistance of the resultant mixture. Approach 2 resulted in an RA dosage between Approaches 1a and 1b. Therefore, the research team used Approach 2 to select the optimum dosage.

Figure 1. Example of Approach 1b: Optimum RA Dosage Determination by Targeting the Low Temperature of the “20%RAP-BR” Grade

Figure 2. Example of Approach 2: Optimum RA Dosage Determination by Targeting the Low Temperature of the “PG xx-28” Grade

BINDER BLENDING ANALYSIS

The addition of recycled asphalt materials to virgin binders significantly increased the stiffness of the resultant blends, which would improve rutting resistance but decrease fatigue resistance, thermal cracking resistance, and their stress relaxation property. These effects became more pronounced as the recycled content increased. Adding bio-based RAs counterbalanced these negative effects, where the effectiveness of each RA depended on its chemical composition and its interaction with the type of recycled binder (i.e., RAP or RAS) present in the blend.

Petroleum-based RAs (i.e., asphalt flux) behaved as a softener, restoring the properties of the recycled binders only by physical process. GPC indicated that the chemical composition of this type of RA was similar to an asphaltic material. As a result, the petroleum-based RA was not effective in decreasing the cracking susceptibility of asphalt blends containing RAS. Therefore, it is not recommended for use in mixtures containing RAS.

ΔTc parameter results indicated that binder blends with up to 40% RAP ABR could still meet the preliminary threshold of -5°C after RTFO plus 40 hours of PAV aging, but 15 to 25% RAS ABR increased the cracking susceptibility of the binder blends. LAS tests indicated that blends with 25% RAS ABR substantially reduced the number of cycles to failure per unit increase in strain.

Determining the properties of the binder blends at critical pavement temperatures using standard testing equipment (i.e., DSR and BBR) was found to reliably capture material incompatibilities and potential inefficiencies of RAs. Furthermore, this approach could guide the use of appropriate proportions in a binder blend (i.e., virgin binder, recycled asphalt materials, and RA). Since the type (i.e., chemistry) of the RAs influences the aging susceptibility and their interaction with the virgin binder and recycled materials, it is necessary to understand how the binder components affect the mixture’s performance properties.

MIXTURE PERFORMANCE TEST FINDINGS

Mixtures with two different aggregates (i.e., gravel and carbonate) were designed to attain ABRs of 20% RAP, 40% RAP, 25% RAS only, and 30% RAP plus 5% RAS combination. The 20% RAP ABR mixes were treated as the control mixes for performance comparison. The higher ABR mixes were rejuvenated with two different bio-based recycling agents at dosages selected using Approach 2. The RA dosages ranged from 2.1% to 5.0% by weight of the total asphalt content. The higher ABR contents were selected based on the current limits specified by WisDOT.

HWTT results showed that all of the rejuvenated mixes at higher ABRs had better rutting and moisture resistance than the control mixtures. Although, all of the rejuvenated mixes had lower IDEAL-CT CTIndex values than the control mixes, indicating reduced intermediate-temperature cracking resistance, only three mixes failed the preliminary minimum CTIndex criterion of 40 from a previous WHRP study. Two of those mixtures barely failed this criterion.

All of the rejuvenated mixes at high ABR except one had higher DCT fracture energy values than the control mixes, indicating potentially improved thermal cracking resistance. In addition, all of the mixes exceeded the minimum fracture energy criterion of 300 J/m2 that has also been recommended for Wisconsin mixes.

|E*| showed inconsistent results for the rejuvenated mixes after STOA and LTOA when compared to the control mixes. Some of the rejuvenated mixes had higher stiffnesses while others had lower stiffness. The same inconsistency was observed for the Glover-Rowe parameter for mixtures (G-Rm). G-Rm aging ratios showed that the rejuvenated mixes had similar aging susceptibilities as the control mixes without RAs, except for one rejuvenated mix.

Asphalt mixtures with innovative materials and high recycled contents can be better optimized with a balanced mix design approach. This will enable mix designers to determine the most cost-effective combination of materials to meet all of the mix performance test requirements. In this study, HWTT and DCT results exceeded the preliminary thresholds for Wisconsin mixtures, while some of the recycled mixtures with RAs barely failed the IDEAL-CT criteria. Therefore, slight adjustments to the dosage of RAs and/or the total binder content would be expected to provide high recycled content mixtures with balanced rutting and cracking performance.

RECOMMENDATIONS FOR IMPLEMENTATION

A step-by-step guide was developed to evaluate the quality of asphalt blends with high recycled contents and RAs to produce recycled asphalt mixtures with balanced rutting and cracking resistance. The design steps are briefly summarized as follows:

- Extract and recover the RAP and/or RAS binder.

- Determine the high-temperature and low-temperature performance grades of the component materials (i.e., virgin binder, RAP binder, and RAS binder) to be used for blending.

- Blend the virgin binder with the recovered RAP and/or RAS binder(s) at the desired ABR(s) content.

- Age the binder blend using the aging protocol of RTFO plus 40 hours in the PAV.

- Perform the BBR test on the aged blend from step 4.

- Determine the optimum RA dosage to achieve the low-temperature grade based on climatic requirements. For bio-based RAs, an initial dosage of 5% by weight of total binder (i.e., virgin plus recycled binders) is recommended, while an initial dosage of 20% by weight of total binder is suggested for a petroleum-based (i.e., asphalt flux) RA.

- Conduct mixture performance tests to assess compliance with BMD performance criteria. If the IDEAL-CT criterion is not satisfied, increase the RA dosage and verify IDEAL-CT and HWTT at the higher RA dosage.

The study also recommended adding a new section for Recycling Agents to the specifications with the following suggested wording: “Recycling agents can be used to help meet the performance test requirements of mixes containing high recycled contents. Petroleum-based (i.e., asphalt flux) recycling agents should not be allowed in mixtures containing RAS as binder replacement.”