- Fall 2021

Recent Friction Studies at the NCAT Test Track

Given that the NCAT Test Track is surfaced with a wide variety of asphalt mixtures and surface treatments that utilize a range of aggregate types and gradations, it is an ideal platform to conduct tire-pavement friction research. The closed facility’s extensive range of pavement surfaces with distinct friction characteristics is perfect for conducting studies to examine how friction changes with traffic and time, how aggregate properties and pavement surface textures influence friction, the performance of special surface mixes and treatments, and to compare different friction measurement devices.

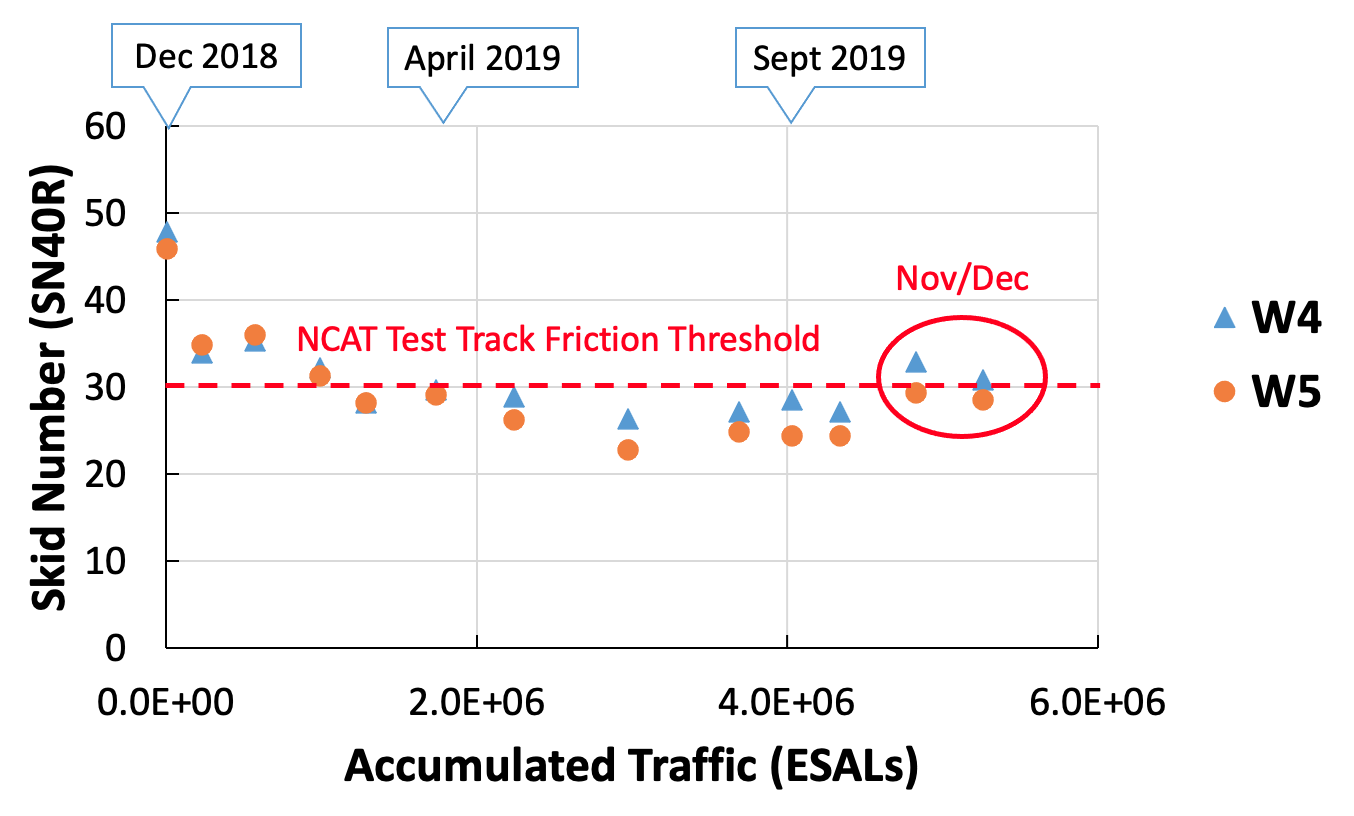

West Virginia Division of Highways (WVDOH) recently sponsored a study to evaluate the feasibility of increasing the dolomite content in surface mixtures. West Virginia has a source with an abundance of dolomites, but they are known to be highly susceptible to polishing. Two test sections, W4 and W5, were built in 2018 using 70% and 90% dolomite coarse aggregates in the surface course, respectively. Dynamic friction tester and locked-wheel skid trailer (LWST) tests were conducted to determine the friction performance of these two sections.

Figure 1 demonstrates that replacing sandstone coarse aggregates by 70% and 90% dolomite resulted in asphalt surface mixtures with fairly low long-term skid resistance. These results validated WVDOH’s requirement that dolomite shall not exceed 50% of coarse aggregate in asphalt surface mixtures when the projected traffic volume is greater than 3 million equivalent single axle loads (ESALs).

Figure 1. Friction Performance of NCAT Test Track Sections W4 and W5

Shotblasting the pavement surface has been used as a technique to restore the skid resistance of polished pavement. As shown in Table 1, the shotblasting system consists of a shot propeller to blast the steel balls, a vacuum unit to recover the abraded material from the road surface, a magnetic separator to collect the steel shots for reuse, and a residue container, followed by a power broom to sweep away residual loose particles. This technique was used for five test sections with low skid resistance (skid number <30) at the Test Track.

Shotblasting system on Section W5 at the NCAT Test Track.

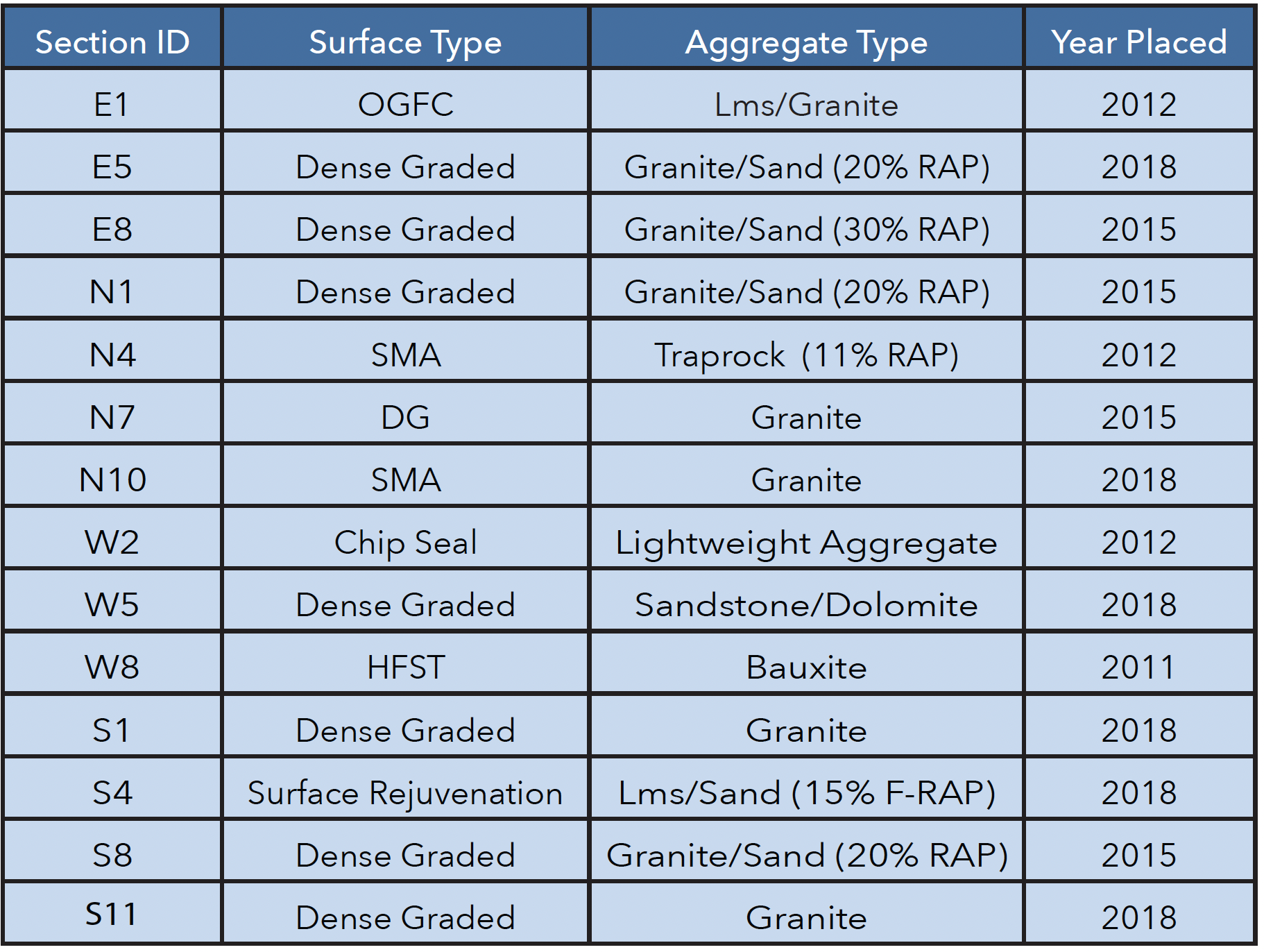

Table 1. Sections from the NCAT Test Track Selected for Use in 2020 Friction Study

According to the measurement results, the surface friction and texture properties of the test sections were substantially improved immediately after shotblasting treatment. The surface mixture and aggregate types were significant factors affecting the capability of the shotblasting treatment to restore friction and texture characteristics. After 5 million equivalent ESALs of trafficking, the shotblasting treated sections still had skid numbers above 30, indicating the effectiveness of this treatment. The shotblasting technique was not detrimental to the pavement condition in terms of roughness, rutting, or cracking.

In 2020, another study evaluated the repeatability of friction measurements using the LWST and the sideways-force coefficient routine investigation machine (SCRIM). As presented in Figure 3, this study included 14 test sections with different surface texture and friction characteristics. The LWST and SCRIM tests were conducted at 30, 40, and 50 mph test speeds and different test times (or temperatures) on two consecutive days.

This study found that an acceptable precision of friction measurements was within 2.5 skid number units or 3 skid resistance units. In addition, the study concluded that the LWST skid number and SCRIM readings had a good linear correlation, particularly in the straight test sections. This study confirmed that increasing test speed or test temperature reduced the measured friction values. Regression models were developed to correct the friction measurements at any given speed or temperature to a reference speed or temperature.