- Spring 2023

Assessing the Sensitivity of the IDEAL-CT and the I-FIT to Polymer Modification

As the asphalt pavement industry moves toward the implementation of balanced mix design (BMD), asphalt practitioners have been exploring innovative approaches to design asphalt mixtures with balanced rutting and cracking resistance. One potential approach is polymer modification to improve the quality of the asphalt binder. However, several existing studies found that using polymer modified asphalt (PMA) did not improve the cracking resistance of the mixture measured in the Indirect Tensile Asphalt Cracking Test (IDEAL-CT) and the Illinois Flexibility Index Test (I-FIT). This finding contradicts the superior cracking performance of many field projects using PMA versus unmodified asphalt mixtures, highlighting a potential limitation of the IDEAL-CT and the I-FIT as not being sensitive to polymer modification.

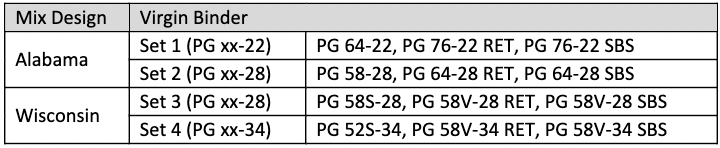

Table 1: Mix Design and Virigin Binder Summary

In a recently completed National Road Research Alliance (NRRA) study, researchers at NCAT and Mathy Technology and Engineering Services, Inc. (MTE) assessed two hypotheses for the lack of sensitivity of the IDEAL-CT and the I-FIT to polymer modification:

- Hypothesis 1 is “Testing the IDEAL-CT and I-FIT at the volumetric optimum binder content (OBC) of the mixture is not sufficient to capture of the benefits of polymer modification.” Many Superpave asphalt mixtures are lacking asphalt binder and thus have inadequate cracking resistance. Using PMA in these mixtures will improve the overall quality of the asphalt binder, but this improvement is not sufficient to affect the cracking resistance of the mixture. In other words, polymer modification alone cannot fix a “dry mix” issue. In this case, more asphalt binder would be needed to capture the benefits of polymer modification on improving the IDEAL-CT and the I-FIT results.

- Hypothesis 2 is “The IDEAL-CT and I-FIT must be conducted at an equal stiffness condition to properly assess the cracking resistance of PMA versus unmodified asphalt mixtures.” Currently, both tests are conducted at 25°C with a constant loading rate of 50 mm/min, and the final cracking index parameters [cracking tolerance index (CTIndex) for the IDEAL-CT and flexibility index (FI) for the I-FIT] are calculated based on the fracture energy (Gf) and the post-peak slope of the load-displacement curve. A high Gf and a moderate post-peak curve are desired for good cracking resistance. Polymer modification tends to stiffen the asphalt binder but while making it more ductile at the same time. As a result, the PMA mixture will have a higher Gf but a steeper post-peak curve, which could yield a similar or lower CTIndex and FI value than the unmodified mixture. This limitation could be addressed by running the test at an equal stiffness condition to better characterize the impact of the binder’s elasticity and relaxation property on the cracking resistance of the mixture.

The study includes two mix designs (one from Alabama and one from Wisconsin) and four sets of virgin binders. As shown in Table 1, each set of virgin binders included an unmodified binder, a styrene-butadiene-styrene (SBS) modified binder, and a reactive ethylene terpolymer (RET) modified binder, where the two modified binders were formulated with the same unmodified binder to avoid the confounding impact of different base binders. The Alabama mix design was a 9.5 mm NMAS Superpave mixture with 20% RAP, and the Wisconsin mix design was a 12.5mm NMAS Superpave mixture with 23% RAP. The volumetric OBC of the two mix designs were 5.5% and 5.1%, respectively.

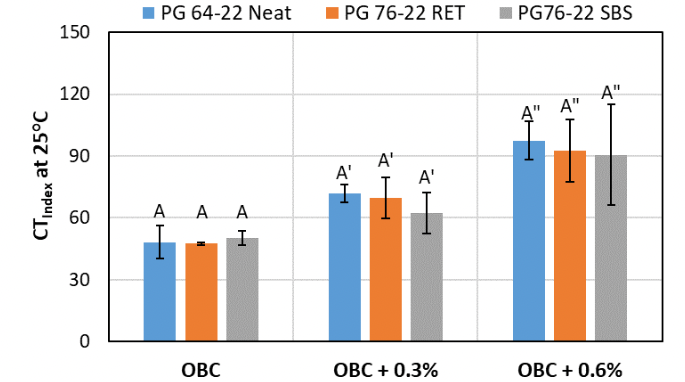

To assess the first hypothesis of the study, each mixture was tested with the IDEAL-CT and the I-FIT at three binder contents: volumetric OBC, + 0.3%, and + 0.6%. Both tests were conducted at 25°C following the current ASTM and AASHTO procedures. Test results were compared across the three virgin binders at each binder content to determine if increasing the binder content beyond the volumetric OBC could better capture the improved cracking resistance of the mixture due to polymer modification. Figure 1 presents the IDEAL-CT results of the Alabama mixtures with PG xx-22 binders for illustration purposes. Increasing the binder content consistently increased the CTIndex of all the mixtures, indicating improved cracking resistance. However, at all binder contents, the two PMA mixtures had statistically equivalent CTIndex results as the unmodified mix, which indicated that the CTIndex was not sensitive to polymer modification regardless of the binder content. The IDEAL-CT and the I-FIT results for the other combinations of mix designs and virgin binders showed similar trends.

Figure 1: IDEAL-CT Results of Alabama Mixtures with PG xx-22 Binders at 25°C.

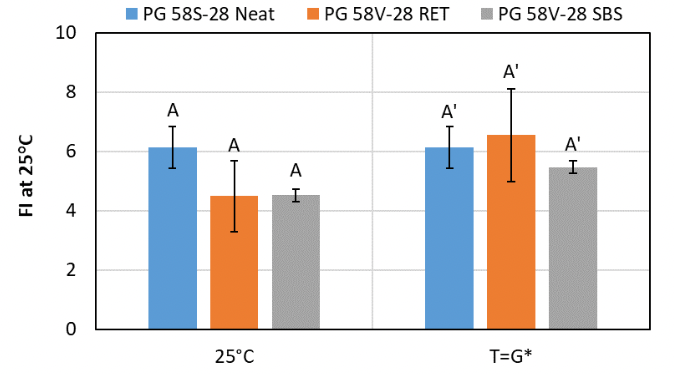

To assess the second hypothesis of the study, additional IDEAL-CT and I-FIT testing at the volumetric OBC was conducted at an equal stiffness temperature (T=G*) in addition to 25°C. The T=G* was determined based on the Torsion Bar Modulus test, which varied from 22 to 25°C among the Alabama mixtures and 19 to 28°C among the Wisconsin mixtures. Figure 2 presents the I-FIT results of the Wisconsin mixtures with PG xx-28 binders at 25°C and T=G*. At both test temperatures, the two PMA mixtures had statistically equivalent FI results as the unmodified mixture when the test variability was considered. Similar findings were observed in the IDEAL-CT results, which indicated that adjusting the test temperature to T=G* did not help discriminate the cracking resistance of PMA versus unmodified mixtures.

Figure 2: I-FIT Results of Wisconsin Mixtures with PG xx-28 Binders at 25°C versus T=G.

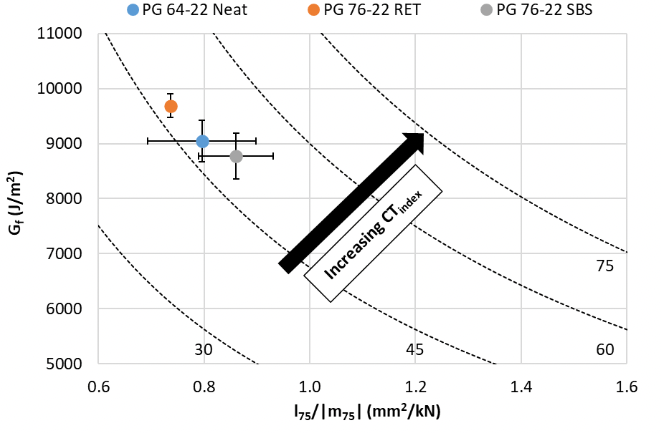

In addition to assessing the two hypotheses discussed previously, the IDEAL-CT and the I-FIT results were also evaluated using the interaction diagram analysis developed in Yin et al. (2023). The analysis showed that in most cases, polymer modification had a notable impact on the load-displacement curve, but its impacts on the fracture energy (Gf) and the post-peak parameters tended to offset each other on the CTIndex and the FI value. As shown in Figure 3, the direction of change in the IDEAL-CT and the I-FIT results due to polymer modification on the interaction diagram was almost perpendicular to the direction of increasing CTIndex or FI. As a result, the PMA and unmodified mixtures fell on similar CTIndex and FI contour curves despite having different Gf and post-peak parameters.

Figure 3: IDEAL-CT Interaction Diagram of Alabama Mixtures with PG xx-22 Binders at 25°C.

In summary, the study concluded that the current IDEAL-CT and I-FIT procedures and parameters are not sensitive to polymer modification. Future research was suggested to explore alternative parameters from the interaction diagram analysis that could discriminate PMA versus unmodified mixtures. In the meantime, SHAs were suggested to use the same IDEAL-CT and I-FIT criteria for asphalt mixtures containing PMA and unmodified binders with the same base binder grade. More detailed results and findings of the study can be found on the NRRA website.

Contact Fan Yin for more information about this research.