- Spring 2017

Is Your Gsb Correct?

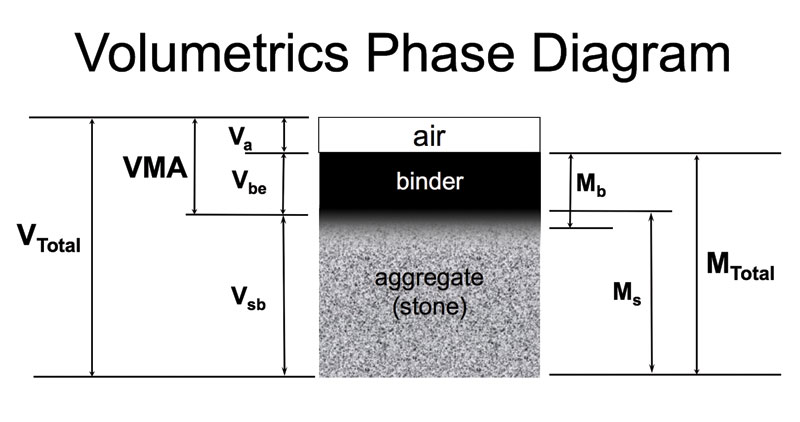

Aggregate bulk specific gravity may be one of the least appreciated factors affecting the performance of asphalt pavements. Although high quality mixtures can be made with aggregates having a wide range in bulk specific gravity values, precisely determining the bulk specific gravity (Gsb) is critical to setting the optimum asphalt content of every mix design. Volumetric mix design criteria for air void content (Va) and voids in the mineral aggregate (VMA) set the minimum volume of effective binder (Vbe) for a mixture: Vbe = VMA – Va.

However, calculation of a mixture’s correct VMA is highly dependent on an accurate determination of the Gsb. An error in Gsb can result in too much or too little asphalt in the mix design and ultimately lead to a variety of asphalt pavement performance problems such as rutting, raveling, bleeding, and cracking.

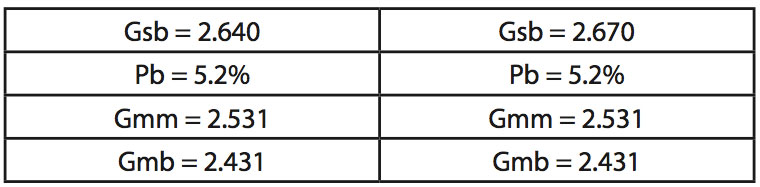

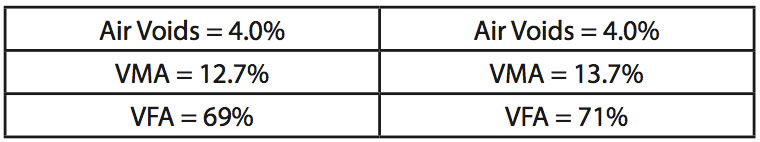

Unfortunately, there are considerable issues of accuracy and variability associated with Gsb determinations. A relatively small error in the blend’s Gsb has a significant effect. As illustrated below, a difference in Gsb of 0.030 (a difference that is well within the repeatability of Gsb results) can change the VMA by 1.0% for a mixture, easily changing a failing mix design into a passing mix design.

Given:

Calculated:

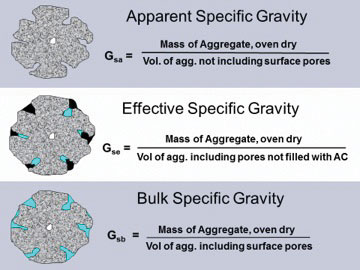

A fundamental check that should be part of every mix design is making sure that the relationships Gsa > Gse > Gsb are correct. The apparent specific gravity, Gsa, of each aggregate component is determined from the same measurements used to determine Gsb, so no extra effort is involved. Gsa of the aggregate blend is calculated in the same way as Gsb for the blend. Gse is determined independently, calculated from the mixture’s maximum theoretical specific gravity, asphalt content, and the specific gravity of the asphalt binder. Ensuring that these three aggregate specific gravity values are in the right order is a reality check on the testing. If Gsb > Gse, then it would mean that the asphalt absportion is negative; if Gse > Gsa, then it would mean that the aggregate absorbs more asphalt than water – both non-sensical results.

One of the most important policies an agency makes is determining who sets the Gsb for the aggregates used in mix designs. There are three basic approaches:

- Gsb set by the aggregate suppliers,

- Gsb set by the mix designers, and

- Gsb set by the agency.

Each of these approaches has advantages and disadvantages. Allowing mix designers to set Gsb values is probably the most common and the most efficient approach, but a process must be established to independently verify the Gsb values. Even then, given the wide range of allowable differences in Gsb values between two labs, there are opportunities to abuse the system. When the aggregate suppliers set the Gsb, they provide that third-party independence, except for those cases where the aggregate supplier and the asphalt producer are the same company. Aggregate supplier set values also establishes Gsb consistency for each aggregate product. For example, multiple contractors using the same aggregate material from a source have to use the same value in their mix designs. Having the highway agency set the Gsb values for every aggregate product is the most fair and reliable approach but puts a tremendous burden on the agency to test so many products. The frequency of checking Gsb should be based on historical data for how much Gsb values change over time.

Gsb for reclaimed asphalt pavement (RAP) aggregate should be based on a method proven to provide the most suitable values for the aggregates used in the state. Gse should not be used for RAP. Doing so will inflate the calculated Gsb for the aggregate blend and make the VMA appear higher than it actually is. For mixtures containing RAP, more caution should be used in the approach of determining optimum asphalt content. NCAT can provide an Experimental Guide for Identifying the Best Method for Determining the RAP Aggregate Bulk Specific Gravity for a State or Region.

Another Gsb issue to consider is dealing with natural variations that occur in aggregate materials over time. Some aggregate sources may have very consistent Gsb values over decades, whereas others have significant variations within a single year due to the site’s geology and mining operations. In cases where mix designs are valid for a year or two and the Gsb changes by more than 0.020 over that time, then there is a risk that the VMA calculated with the original Gsb values is not valid. Since some agencies use VMA as part of acceptance testing, there is a strong chance of accepting a poor mix or rejecting a good quality mix due to the unknown changes in Gsb. Regularly checking Gse during mix production and comparing the values to the Gse from the mix design is a good way to catch variations that occur in the natural materials.