Evaluation of Mixes Containing REOB/VTAE with I-FIT Procedure

Re-refined engine oil bottoms (REOB), also known as vacuum tower asphalt extenders (VTAE), are a product of the engine oil recycling process. After recovered engine oils have been tested to insure the oil is free of hazardous contaminants and water is removed they enter the re-refining process. The oil is subjected to atmospheric distillation followed by vacuum distillation. The nondistillable fraction from this process is the REOB/VTAE. Although REOB/VTAE have been used to modify asphalt binders since the 1980s, concerns have recently been expressed in the asphalt paving industry due to a lack of comprehensive research. In a study sponsored by Heritage Research Group (HRG), NCAT recently performed a limited analysis on the impact of REOB/VTAE containing binders on the cracking resistance of asphalt paving mixtures.

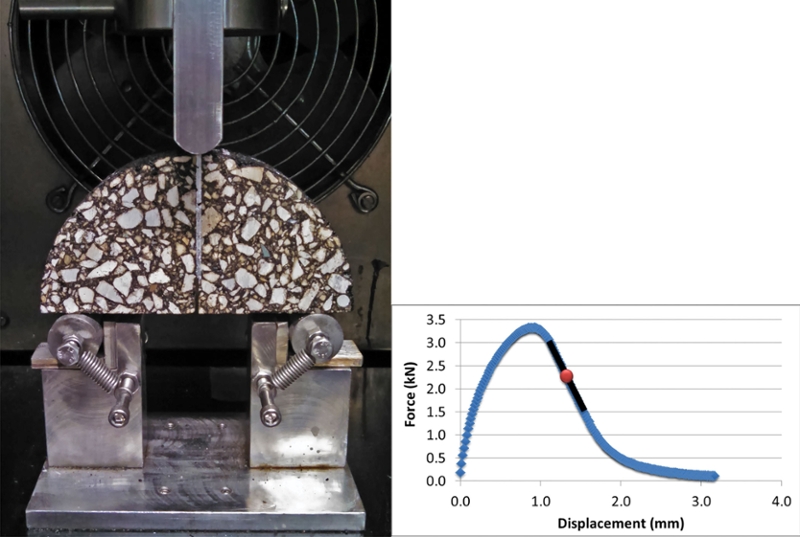

The first phase of the study involved laboratory preparation and testing of seven asphalt mixture samples using the Illinois Flexibility Index Test (I-FIT). The I-FIT test setup used for this study and an example I-FIT data file are shown in Figure 1. The I-FIT test determines two parameters, the Fracture Energy and the Flexibility Index. The Fracture Energy is the area under the load-displacement curve and represents the energy required to fracture the asphalt specimen. The Flexibility Index is calculated by dividing the Fracture Energy by the slope of the load-displacement curve at the post-peak inflection point. In general, a steeper post-peak slope is indicative of a more brittle mix.

Figure 1: I-FIT Test Setup (left) and Example I-FIT Data (right) with Post-Peak Slope Highlighted

I-FIT samples were prepared for each mix using both short-term and long-term oven aging in accordance with AASHTO R30. The base PG (Performance Based) binder for this study was a PG 58-28. One mix contained the base binder without REOB/VTAE, and the remaining mixes contained one of two REOB/VTAE products (Source A and Source B) at dosage rates of 3%, 6%, and 9% by weight of virgin binder. All materials were formulated to meet PG 58-28 specifications and a mix design was provided by HRG using Illinois DOT materials.

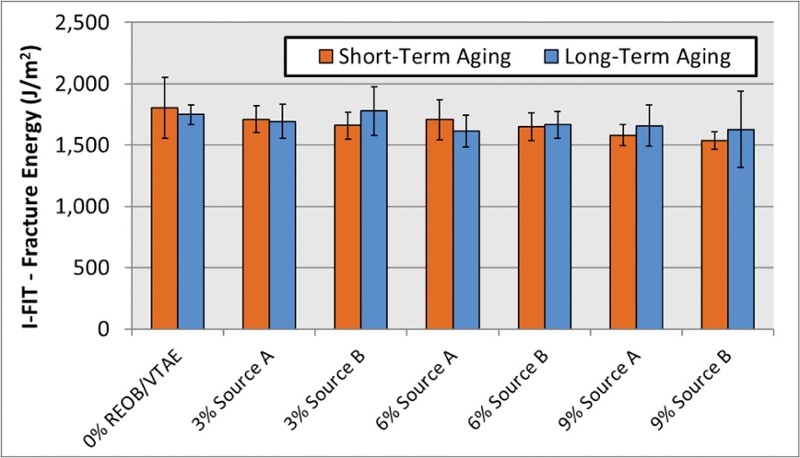

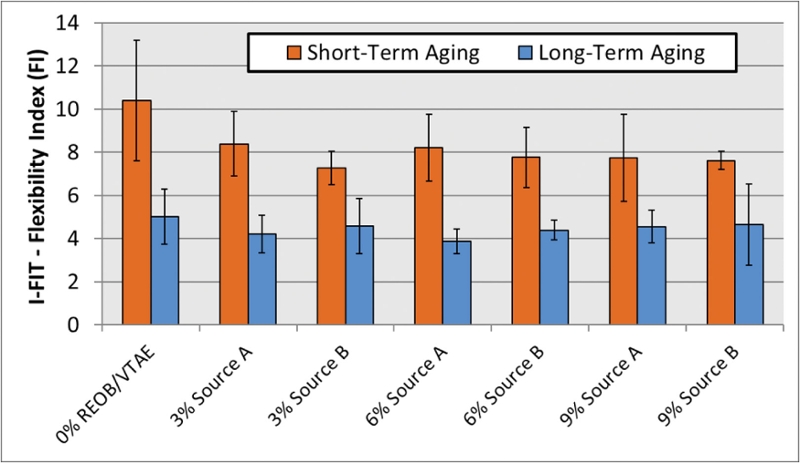

A statistical analysis was performed to determine which factors (REOB/VTAE dosage, REOB/VTAE source, and aging process) had a significant impact on the two I-FIT result parameters (Fracture Energy and Flexibility Index). The analysis showed that none of the experimental factors had a significant impact on the Fracture Energy results. Although long-term oven aging and the presence of REOB/VTAE statistically reduced the Flexibility Index, increasing the REOB/VTAE dosage above 3% did not have an impact. The average and standard deviation of the I-FIT Fracture Energy and Flexibility Index for the seven test mixes are shown in Figures 2 and 3, respectively.

Figure 2: I-FIT Average and Standard Deviation of Fracture Energy

Figure 3: I-FIT Average and Standard Deviation of Flexibility Index

An additional analysis was conducted on the Flexibility Index results using a one-way ANOVA to determine the impact of the seven mixes at both the short-term and long-term aged conditions. The results showed that at both aging conditions, the mix without REOB/VTAE had the highest mean Flexibility Index value. At the short-term aged condition, the mix without REOB/VTAE and 3% Source B REOB/VTAE had statistically different results, while the rest of the mixes were statistically equivalent. At the long-term aged condition, all of the mixes had statistically equivalent Flexibility Index results.

The second phase of the study involved verifying the REOB/VTAE content in each binder using inductively coupled plasma (ICP) analysis. Other studies have indicated that zinc and calcium detected in asphalt binders with similar techniques can be correlated to REOB/VTAE contents. The results of the ICP analysis indicate that the asphalt binders used in this study contained approximately 3%, 6%, and 9% REOB/VTAE as reported.

The results of this limited study showed that while REOB/VTAE reduced the average Flexibility Index for short-term aged mixes, long-term aged mixes were not affected by REOB/VTAE. Results also indicate that the source of the REOB/VTAE or dosage rates between 3 and 9% did not statistically affect the Flexibility Index. However, this study is limited in that it only evaluated one set of materials (one mix design and one base binder grade). An expanded evaluation with additional materials is needed. Additional evaluations of this type would be helpful in quantifying the impact of REOB/VTAE on the cracking susceptibility of asphalt mixtures and alleviating industry concerns regarding its use.