Equipment

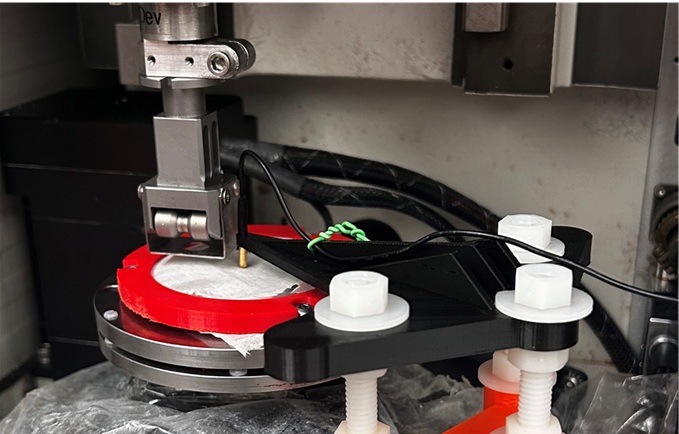

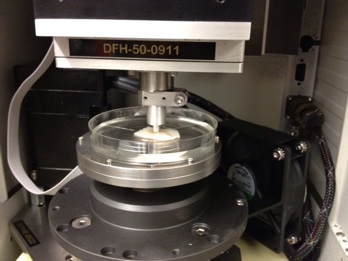

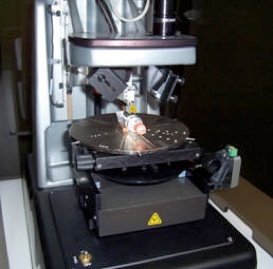

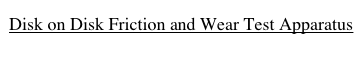

This laboratory has available many useful experimental and computational tools. This includes a Bruker/CETR UMT-3 friction and wear test machine that is capable of measuring the load and frictional torque between a rotating sample and an opposing surface. It has been used for electrified rolling ball on disk testing and many other geometries. The rig is very versatile and can handle samples of many different sizes and materials. In addition, it can be easily adapted to incorporate different geometries such as a three ball test and additional sensors as needed. Data from the rig is digitally recorded through a high speed data acquisition board and PC. The lab also contains the computational hardware, commercial and custom software needed to perform comprehensive tribological simulations. A rotating tire test rig is also available for use.

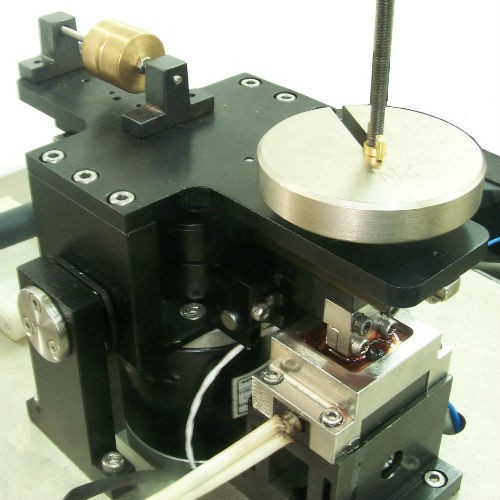

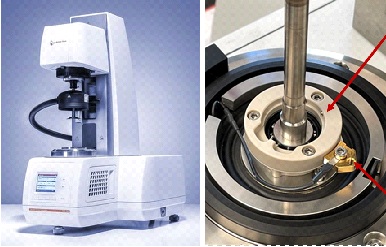

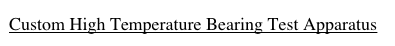

An Anton Paar rheometer is available that also can be fit with tribology tests and a full rolling element bearing test configuration recently created by Anton Paar. The apparatus is designed to hold a 7200-B-XL-TVP angular contact bearing. A spring-loaded contact makes electrical contact with the rotating shaft. The inner race of the bearing is pressed onto the shaft and the outer race is held by an insulated fixture so that electrical current flow is confined to the shaft and bearing. DC and AC currents can be applied to the integrated contacts to mimic EV loading. The shaft and bearing motion is smooth and allows for more precise electrical and tribological measurements of the bearings. The bearing can also be rotated at a speed up to 3000 RPM and controlled at temperatures up to 220ºC.

A Falex Pin on Vee friction and wear test machine is available for standard testing. The lab also has several ring-on-ring fatigue test machines and Polymet rolling contact fatigue test rigs. One unit has already been retrofitted to test bearings at high temperatures for use in the oven conveyors in the food baking industry (see the unit in use here: bearings Baking Bearing Movie). Multiple surface profilometers, atomic force microscopes, scanning electron microscopes, and nanoindentors are also available on the Auburn University campus.

Pictures and more information about the capabilities of each piece of equipment is listed farther below.

The UMT-3 performing a stiffness test on a submerged cartilage sample.

More Equipment Available:

The Alabama Micro/Nano Science and Technology Center (AMNSTC) is also located at and run by Auburn University. The AMNSTC is a multidisciplinary research facility in the College of Engineering that is capable of fabricating a wide range micro and nano-scale components.

The National Center for Additive Manufacturing Excellence (NCAME) on Auburn Universities campus gives us access to the the latest metal printers and mechanical testing. Additive manufacturing, especially metal, is a rapidly growing field and we are researching the surfaces and tribological behavior of additively manufactured parts.

Click on the pictures for additional information