Solar Power Installation on a Remote Colorado Ranch

by Duane Bartley, March 1996.

In the beginning.

In November of 1994 my mother purchased land in the San Luis

Valley in central Colorado. The area is located in Saguache County between the

Sangre de Cristo mountains to the east and the La Garita and Sawatch mountains

to the west. Fifteen miles south of Poncha Pass, elevation 9010 ft -, at the

edge of the booming metropolis Villa Grove, is the turn off to Bonanza (No

joke, Bonanza is 30 miles up this road). The road to Bonanza and our property

is not paved. About ten miles up the road is a tall wooden arched gate to Kelly

Creek Ranch. Again a dirt road, Mom's house is within eyesight about 2 miles

away.

The land is about 8200 feet in altitude. The Sangre de Cristo range is

across the valley and their peaks climb abruptly to over 14,000 feet within

five lateral miles. This creates a stunningly beautiful view. To the west is

the continental divide again at 14,000 plus feet, but there area good 20 to 30

miles of climb to those peaks. This rugged lay of the land created many

unexpected problems in developing a power system for the house and land. To add

to the problems of the land, cold temperatures are inherent to high altitudes.

I also learned about the unusual wind patterns associated with this country.

Originally I thought this would cause problems but later learned they are a

very predictable energy source.

The land is about 8200 feet in altitude. The Sangre de Cristo range is

across the valley and their peaks climb abruptly to over 14,000 feet within

five lateral miles. This creates a stunningly beautiful view. To the west is

the continental divide again at 14,000 plus feet, but there area good 20 to 30

miles of climb to those peaks. This rugged lay of the land created many

unexpected problems in developing a power system for the house and land. To add

to the problems of the land, cold temperatures are inherent to high altitudes.

I also learned about the unusual wind patterns associated with this country.

Originally I thought this would cause problems but later learned they are a

very predictable energy source.

The land is very remote for the most part. Villa Grove has a population of less

than 100, with one general store for the basics and one gas pump. The next

largest and closest town is Saguache (pronounced the same as the Sawatch

mountains)- Saguache has a population of 584, a gas station, and a very small

grocery store. Salida is my hometown and is 32 miles away and when we bought

the land it was the only place to get LP gas for the generator. Salida is at

least a real town with almost 5000 people, one stoplight, motels, stores, bars,

and of course the mark of civilization, a Wal-Mart. In the opposite direction

from Salida, Alamosa is 60 miles away. It has all the amenities of Salida plus

one institution of higher learning, Adams State College. Between these small

towns I have been able to find most all of the resources I've required. As a

"bonus" my brother lives in Alamosa. He's an explosives engineer at a nearby

goldmine. Not being very mechanically inclined and obviously not prone to

CONstruction he is good for manual labor in those emergency pinches.

Heat, light, and power.

The land is beautiful and quiet, but utilities are obviously a

problem. Cost is always of extreme importance. The land and house had already

absorbed over $80,000- My mother teaches surgical supply and sterile technique

so electricity is not her forte. I checked out all viable options for power at

this remote location. First on the list was the typical idea of the state's

power grid. By far the most reliable and simple once connected, the cost of

connection was extremely prohibitive. The cost quoted to me for power line

installation was over half what had already been invested in the house and

land- To extend a phone line out to the land was going to be $12,000. This was

actually acceptable compared to the $900 a month that the cellular was

costing.

We had a generator put on the land, it was the most reasonable cost and the

fastest to get. The power line was going to take at least two months. The

generator is run on LP that is brought out on a typical propane truck. Although

the generator is very reliable it is also very expensive to run 24 hours a day

As I will explain later, storing the generator's electricity in batteries is

not a good method either The construction was done using the generator, it

worked extremely well The LP we burned ran over $ 100 a week and the generator

only ran during the day. Solar power is not uncommon in the valley and mom

liked the idea of no electric bill, however, the initial investment was not to

her liking. After some convincing, I showed her that the biggest bang for the

buck was solar and we went with that idea.

We had a generator put on the land, it was the most reasonable cost and the

fastest to get. The power line was going to take at least two months. The

generator is run on LP that is brought out on a typical propane truck. Although

the generator is very reliable it is also very expensive to run 24 hours a day

As I will explain later, storing the generator's electricity in batteries is

not a good method either The construction was done using the generator, it

worked extremely well The LP we burned ran over $ 100 a week and the generator

only ran during the day. Solar power is not uncommon in the valley and mom

liked the idea of no electric bill, however, the initial investment was not to

her liking. After some convincing, I showed her that the biggest bang for the

buck was solar and we went with that idea.

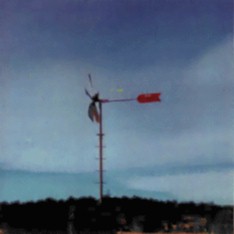

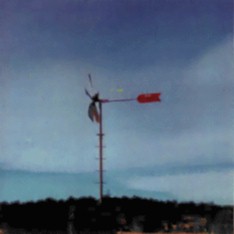

At that time, wind generation of electricity was not available at an economic

level and I wasn't convinced of its reliability. I did however use the wind for

power generation of a different kind.  On the land I have my mustang, and Mom

has our draft team and two other riding horses. The water consumption of these

monsters is unbelievable To satisfy this need I required up to 50 gallons per

day. An electric water pump was not efficient enough for the needs. It also

drained too much from the solar array. In response to this we found a

pneumatic pump that looked perfect for the job. To power the pump we bought a

windmill that ran an air compressor. The well water was 57 feet below the

surface but the pump only required 40 psi to run. The water is stored in a

1500 gallon cistern that was placed in the basement of the house before

construction. Originally, this was left as an open running system. Whenever

the wind blew, the pump ran and filled the cistern. Later I will explain the

potential I found in this source.

On the land I have my mustang, and Mom

has our draft team and two other riding horses. The water consumption of these

monsters is unbelievable To satisfy this need I required up to 50 gallons per

day. An electric water pump was not efficient enough for the needs. It also

drained too much from the solar array. In response to this we found a

pneumatic pump that looked perfect for the job. To power the pump we bought a

windmill that ran an air compressor. The well water was 57 feet below the

surface but the pump only required 40 psi to run. The water is stored in a

1500 gallon cistern that was placed in the basement of the house before

construction. Originally, this was left as an open running system. Whenever

the wind blew, the pump ran and filled the cistern. Later I will explain the

potential I found in this source.

In building the house, the primary objective was functionality and efficiency.

The walls and ceiling have an insulation value of R40. The house is tall

enough for two stories but rather than a dividing floor, most of the house is

open. The office is on a second floor that is created by a loft area. Heating

the house is a lot easier this way. All lights in the house are surrounded on

the wall side by mirrors. This enhances illumination and reduces the number of

lights needed. To further help lighting, all walls inside are painted in a

textured gloss white. Windows in the house are double pane glass for high

insulation value. The roof line runs north to south. The south wall is almost

all glass giving the benefit of plenty of free heat in the winter when the sun

is low in the southern sky. The north-south roof line is excellent all year

for early morning and late afternoon heat collection. In this altitude it is

always cold enough to need heat, There are less than four weeks of 80 degree

weather. The basement has only two small windows, it is always at a cool 58

degrees. In the summer it is a perfect source of "air conditioning." In the

winter it is easier to warm 58 degree air up to 70 than it is to warm -30 air.

The basement is also good closed off and used as a sort of root cellar. The

basement is where all the electronics and storage batteries are kept as well as

the drinking water tank.

Independence Day.

Construction was completed June 1995, time to hook the place up.

The solar array started as four panels with 12 volt, 40 W nominal ratings. The

installers hooked them up as two panels in series then tied the two sets in

parallel with each other. The array gave me a 24 volt nominal rating with a

peak current output of 4.5 amps. The company that supplied the panels told me

they would supply enough power to run the house as long as the occupant was

conservative with usage. To this day I do not know where he got that idea.

This arrangement only allowed for a couple hours of television and lights out

couldn't be past 10 o'clock.

Shortly after installation while mom was watching the news for one of the two

available hours, the weather fixed the solar power problem. The support

structure gave way in one of the valley's typical 60-70 mph wind storms The

wreckage was written off as a total loss- insurance replaced the four originals

with six panels with 105 W rating. I built the second structure and made sure

mother nature wouldn't wreak havoc so easily. In addition to simplifying the

hook-up, I made room for addition and kept it simple so that mom could

understand the basics of operation and repair. The wrecked panels were left at

the ranch and they afforded me the opportunity to tinker. A little

disassembly, creativity, and ingenuity brought life back to the old panels and

greatly expanded my understanding of the photovoltaic panels. I found all of

the actual cells in all four panels were functional, the damage was done to the

contacts on and between the cells. Solder, one iron, copper wire strands, super

glue and of course duct tape were all I needed to repair the old array. Mom

later purchased six more panels from a local auction for an incredible price.

After all was said and done the array was 14 feet long, 4 feet tall and

generated over 20 amps in direct sunlight. The windmill capable of 250 psi

was set up and ran well. It fed compressed air into what used to be a

40-gallon propane tank. The tank compensated for the times when wind was

scarce. If the tank was fully pressurized to the 250 psi rating, it could

almost fill the 1500 gallon cistern once. In the last year we only had to rely

on the tank three or four times. For security's sake mom bought an electric air

compressor and added tire type inflation hardware, and it has come in handy.

One of the draft horses was able to crush the small pipe that the well's air

line ran through. This cut the air line and bled the tank dry in five

minutes, I can't believe all the elements we've had to protect all the systems

from.

Solder, one iron, copper wire strands, super

glue and of course duct tape were all I needed to repair the old array. Mom

later purchased six more panels from a local auction for an incredible price.

After all was said and done the array was 14 feet long, 4 feet tall and

generated over 20 amps in direct sunlight. The windmill capable of 250 psi

was set up and ran well. It fed compressed air into what used to be a

40-gallon propane tank. The tank compensated for the times when wind was

scarce. If the tank was fully pressurized to the 250 psi rating, it could

almost fill the 1500 gallon cistern once. In the last year we only had to rely

on the tank three or four times. For security's sake mom bought an electric air

compressor and added tire type inflation hardware, and it has come in handy.

One of the draft horses was able to crush the small pipe that the well's air

line ran through. This cut the air line and bled the tank dry in five

minutes, I can't believe all the elements we've had to protect all the systems

from.

The battery bank is kept in a large air tight containment box that is exhausted

to the outside. This is required by law due to hydrogen gas buildup developed

in the recharging process. The battery bank consists of eight six-volt deep

cycle batteries. Two sets of four in-series batteries are tied in parallel.

This gives me amp-hours of stored energy. The bank is small for my taste but

the expense of expanding is high. The batteries are over $125 each and four

must be purchased at a time to be of any use.

The power controller worked perfectly from day one. When the solar array is

generating, the power is diverted to either the charging system or the inverter

as necessary. At night, demand is met by tapping the batteries through the

inverter. I understand how this unit works in that I know how dc is inverted to

ac and charging is simply a matter of greater potential on the array than the

batteries. However, the complexity of this controller is baffling. My mother

didn't go cheap. Knowing how crucial efficiency would be, she purchased one of

the top-of-the-line units. It is rated as one of the most efficient

controllers on the market. The face of the controller gives a full read out of

incoming and outgoing power as well as current battery voltage. Two charge

meters are placed upstairs in high use areas to keep the occupant informed of

power storage level. A full charge on the bank will last two to four days in

"total darkness."

This was determined simply by disconnecting the array after a

full charge. One very nice option to the controller is a feature that allows

the bank to be charged by our 110 volt ac generator This is an expensive

process however. Gas cost has already been mentioned The other problem is that

"hard charging" by the generator greatly diminishes the life expectancy of the

batteries. The customer rep that I talked to said that regularly hard charging

the batteries will cut their life by more than half. The high current is the

cause, the array is basically a 'trickle charge" and is far friendlier to the

bank of batteries

This was determined simply by disconnecting the array after a

full charge. One very nice option to the controller is a feature that allows

the bank to be charged by our 110 volt ac generator This is an expensive

process however. Gas cost has already been mentioned The other problem is that

"hard charging" by the generator greatly diminishes the life expectancy of the

batteries. The customer rep that I talked to said that regularly hard charging

the batteries will cut their life by more than half. The high current is the

cause, the array is basically a 'trickle charge" and is far friendlier to the

bank of batteries

Appliances in the home aren't many. There is no microwave yet. The water

heater, refrigerator and cooking stove run on gas as well as the backup heater.

Most of the heat is supplied by the wood stove, but occasionally 24 inches of

snow will convince mom that the wood stack is too far away and gas doesn't have

to be carried through the snow. The computer, fax and printer are all easily

powered by the bank as well as the lights, stereo, television, VCR, kitchen

gadgets, and water pressurizer .The washer and dryer are run directly off the

gas generator (WOW! They really eat up some power.)

This is the way the system stands today

Office Household Appl. Total Power

Equip.

Computer 145 W Entertainment 150 W Max Use -1008 W

Sys.

Printer 75 W Kitchen 60 W Array max 870 W

Appliances output

Monitor 70 W Lights 450 W

Fax 30 W Phantom draw 28 W

Totals 320 W 688 W -138 W

Average Daily Generation 24 V X 98Ah = 2,352Wh

Average Daily Usage 110 V X 19Ah =

-2,090Wh

Average Daily Total

262Wh

I'm always in contact with mom and today she tells me she's very happy with

what I convinced her would work. I turned her home into a science project which

has not always been to her liking. My mother is quite a handy-woman, having

done a lot of the construction inside and out, but she frequently reminds me

that if it can spark she doesn't mess with it. I don't live there day in and

day out, so if I make a change it has to work, and not jeopardize the system or

comfort of living. This country sounds and looks beautiful but in winter the

harshness of nature can easily turn a failure in the system into a life

threatening situation.

Futures and Options

The system as whole works today. Mother teaches all over the

U.S. and leaves for weeks on end. A ranch hand or a neighbor comes up and

feeds the horses as needed, but the house runs on its own. Her messages and

faxes are received every day and she retrieves them by phone when she's on the

road. The thermostat keeps the place warm and floats and valves keep a good

supply of water on hand. Less than $100 a month keeps gas in the LP tank

weather permitting. The rest of the power is supplied by the array and the

windmill. My job is to make sure that accidents don't happen. If they do, I

need to make sure there is at least one backup system to keep the ship afloat.

There is a short preventative maintenance list that is easy to complete. Right

now all the bases are covered, it would take a catastrophic incident to really

create a problem.

This is where things get exciting. With a fully functional system I can

experiment with ideas without having to hinder the things that work. I've

learned many things about the particular area the house is built in. With this

knowledge I have plans for improved living and power generation that I couldn't

previously use or trust. Everything eventually points to power, there are many

different sources to exploit and the rest of this report is dedicated to the

projects I've started and the ideas I'm developing.

Sun-Day Driver.

The solar array is huge already and expansion will become

cumbersome. To get more from what is there I've begun to build a solar chaser.

The system is a hand built single axis chaser. Rather than using electric

current maximum to drive the chaser, I decided that one driven strictly by

timing would prove to be the simplest and cheapest. I've found the hard way

that complexity only seems to develop bigger problems and shorten tempers.

Throughout the year, daylight lasts between seven and nine hours. These are

the hours of direct sunlight rather than actual daylight. In the short winter

days the sun crosses the sky at an angle of around 30 degrees above the

southern horizon. The summer months put the sun closer to the 75-degree mark.

To compensate for the north-south travel, I used a single leg from a

semi-trailer landing gear that was given to me for free. The array weighs over

350 lbs. when the framing is included and the landing gear is still overkill,

but I couldn't beat the price. The handle's leverage makes this process

simple, so mom will have to give it one crank every four weeks or so. This is

not a precise mechanism, but it works. As for east-west travel I've built what

is essentially a pneumatic tic-toc. Air pressure trickles into a cylinder, As

the pressure builds the piston extends out, pushing a toothed flywheel around

by one tooth. This triggers a valve releasing the cylinder pressure and

bringing the piston back to the starting position. The process then begins

again and continues "endlessly." A pressure regulator determines the speed of

the piston and therefore the speed of the sun chaser. The flywheel should take

24 hours to make one revolution. My mock up works on a small scale but it

doesn't have 350 lbs. of solar array on it either.

Right now the array develops four amps by 9-30 A.M. and climbs as high as 17

amps by noon. In the afternoon, it stays above eight amps until 4 PM then

typically drops to close to four amps by 6:30 when the sun sets. One day, with

some help I moved the entire array by hand every hour and found that the chaser

would almost double the current generation of the array. My plan is to

implement this chaser by July of '96. As a safety I will put in a release that

will let the array fall back to "flat" in the event of a failure.

Another use of available space came to me when 1 noticed that the barn roof

faced directly south and was built using 2x8 rafter beams. With this kind of

support the roof could easily accommodate the weight of several hundreds of

pounds of solar heat collection panels. These panels are typically 4x8 sheets

covered by traversing PVC tubes The tubes are painted or dyed black and carry

water. Sides are built around the perimeter and a sheet of glass or Plexiglas

encases the tubes. As the sun shines into this miniature greenhouse, it heats

the tubes and therefore the water in them. One small water pump can be run off

an accompanying photovoltaic solar cell. The water is pumped through and the

heat is stored in either a huge water reservoir or it can be used to run an

extremely small scale steam turbine generator. For the ranch, I like the heat

storage idea. The horses would love a warm place to get out of the frigid

winter air and it could reduce the need in the house to burn wood which causes

pollution. I'm not throwing out the steam generator idea yet but I'll need a

lot more information and resources before I attempt tapping that energy

Another use of available space came to me when 1 noticed that the barn roof

faced directly south and was built using 2x8 rafter beams. With this kind of

support the roof could easily accommodate the weight of several hundreds of

pounds of solar heat collection panels. These panels are typically 4x8 sheets

covered by traversing PVC tubes The tubes are painted or dyed black and carry

water. Sides are built around the perimeter and a sheet of glass or Plexiglas

encases the tubes. As the sun shines into this miniature greenhouse, it heats

the tubes and therefore the water in them. One small water pump can be run off

an accompanying photovoltaic solar cell. The water is pumped through and the

heat is stored in either a huge water reservoir or it can be used to run an

extremely small scale steam turbine generator. For the ranch, I like the heat

storage idea. The horses would love a warm place to get out of the frigid

winter air and it could reduce the need in the house to burn wood which causes

pollution. I'm not throwing out the steam generator idea yet but I'll need a

lot more information and resources before I attempt tapping that energy

"Thar she blows"

The wind energy potential of this area is truly surprising. I

tried to spend a couple of days doing nothing but vacationing and found I

couldn't. I got up at 6 a.m. to feed the horses. The air was crisp, cold, and

fresh, and not moving. Not good when you need wind to run windmills. By 7 a.m.

the sun was shining on the peaks to the west and I noticed there was an eight

to 15 mph westerly wind within about half an hour. In the evening the opposite

happened, an easterly wind began within half an hour of the sun setting behind

the peaks. After a week of the same pattern I realized it was convection

currents of the air in the mountain valley. Even on calm days this wind is

there in the morning and afternoon. The area is also known for gale force winds

due to the funnel effect the valley has on weather patterns. Last month the

compressor on the windmill was detonated when the high wind break-off on the

mill failed and allowed the blades and compressor to critically over speed.

The unit was replaced at the cost of the manufacturer due to a construction

defect. The potential of this wind has given me two ideas I'm pursuing.

The wind energy potential of this area is truly surprising. I

tried to spend a couple of days doing nothing but vacationing and found I

couldn't. I got up at 6 a.m. to feed the horses. The air was crisp, cold, and

fresh, and not moving. Not good when you need wind to run windmills. By 7 a.m.

the sun was shining on the peaks to the west and I noticed there was an eight

to 15 mph westerly wind within about half an hour. In the evening the opposite

happened, an easterly wind began within half an hour of the sun setting behind

the peaks. After a week of the same pattern I realized it was convection

currents of the air in the mountain valley. Even on calm days this wind is

there in the morning and afternoon. The area is also known for gale force winds

due to the funnel effect the valley has on weather patterns. Last month the

compressor on the windmill was detonated when the high wind break-off on the

mill failed and allowed the blades and compressor to critically over speed.

The unit was replaced at the cost of the manufacturer due to a construction

defect. The potential of this wind has given me two ideas I'm pursuing.

First is the simple expansion of storage capacity for the compressor. The

compressor currently fills the 40-gallon tank to 250 psi and then folds the

blades parallel with the wind so that the tank isn't over pressurized. With a

500-gallon tank ( identical to the one that currently holds LP gas) I could

increase storage more than ten times, This could be used to operate pneumatic

tools or, more realistically, be used to run an air motor as a prime mover for

a 24V generator. The prime mover/generator was easy to build. I cheated by

buying the four needed components. My uncle calls this checkbook engineering

but I did get it to work. The air motor is fed by the tank through a pressure

regulator. It is then directly connected by a sleeve to the regulated

generator. The air motor was $109 through Grainger, the reg. was only $15 and

the generator came from a military 2 1/2 ton truck engine. The sleeve was hand

made. Through this hardware the efficiency comes out at less than 30% but it

seems to me to be free power since the compressor would simply let it go

otherwise.

My second idea for the use of wind power is again checkbook engineering.

Southwest Windpower has developed a $550 starter turbine. With 28 mph wind,

the turbine generates 300 watts and in extreme wind speeds the unit is self

preserving and begins to stall at max output. Many people in outlying areas

have used technology like this to live "off the grid" and generate all of their

own power. This unit mounts to the roof where the blades are free of wind

deformation developed by trees, trucks, horses, or anything else that causes

problems. My only concern is the possibility of "hard charging" during high

winds on a cloudless day. The advantage of charging at night might lead to the

ability to run the washer and dryer off the batteries without fear of running

the bank low. I'm very hopeful that this will allow the luxury of using power

on the ranch without worrying over battery supply. By August I should have the

money to buy the unit for the house as a birthday present to Mom. At least

this idea is simply an add-on, it can only improve what we've already got.

Power so Strong you can Smell it

As I was tweaking the solar array one morning, my wife came out

of the house and pointed out an article in one of my tech-junkie magazines.

She said "Did you see this methane plant these people built?" I told her yes

and that I thought it was really interesting but way out of my league in the

area of "building and idiot proofing." My veterinarian wife stopped me and said

"Actually, they built a cow and hooked its tail end to a gas tank." Her

complete understanding of the physiology of this "cow" piqued my curiosity and

I began to investigate. Construction of the beast is thoroughly explained with

the aid of blueprints and a video tape. That only leaves the end use to

question. The article said that with minimum modifications, the generator,

fridge, water heater, space heaters, and any other propane fueled equipment

could be converted to use methane gas. Safety was my primary concern and the

article assured me there was no problem with this source.

A small scale methane generation plant is simple in theory. A vat is half

filled with water, then add organic material consisting of animal waste

(supplied by five horses), and another source rich in carbon such as straw,

grass, vegetable matter, or even news print. The water is where the bacteria

grow and the organic material makes a thick fibrous mat that floats on the

water. Above the mat is where the methane collects after the bacteria digests

the usable slurry. The vet said in order to keep it "healthy" the cow needs

the carbon source to give the slurry mix a carbon to nitrogen ratio of 30:1.

Manure by itself has a C:N ratio of 15:1. Feeding two five-gallon buckets of

manure per day with a little vegetable matter will generate between 100 and 200

cubic feet of methane per day. This is more than adequate for what is needed

on the ranch. I'm looking at building a unit that is about half that size. The

gas developed does reek as expected so to alleviate that it is bubbled through

a mixture of water and ag lime. This not only makes the gas odorless, it also

removes its corrosive properties. The "cleaned" gas is stored in another

tank

resembling a medium coffee can inverted in a large coffee can. The large can

is half filled with water and when the gas is bubbled in, it is contained and

slightly pressurized by the weight of the medium can. These cans would actually

be large tanks of 200 gallons or more. The stored gas contains about 900 Btu

per cubic foot and an octane rating of well over 100.

This is a big project and may take a couple of years to get together but I

personally am very excited about doing it. With the assistance of my

veterinarian/wife I think we could pull this off. Other benefits of the system

include a huge supply of odorless nutrient rich fertilizer that is

naturally aged. The methane produced burns with a clean blue flame and only

CO2 and water vapor are given off. I learned that many hog farmers in the

Midwest use these methane plants. There are 18 large scale units operating in

the U. S that produce 60,000 to 70,000 cubic feet of gas a day so they do work and it's not an untried idea.

No such thing as 'free lunch"

Probably my most practical idea comes from my hatred of feeding

ungrateful animals at 6 a.m. I knew a rancher who seldom had time to ride his

horses like they needed to be. To maintain their health, he purchased a

walker. A lot of people do this but I think they got it backwards. A walker

works by powering an electric motor that drives an elevated merry-go-round.

The spokes of the merry-go-round are above a horse's eye level by at least 1.5

feet. A chain dangles from each spoke and is clipped on a horse's halter. The

motor drives the walker, the walker pulls the horses at a walking pace, and the

horses get their needed exercise. This is all wrong to me. If I feed it I don't

think I should pay to walk off the food I just fed the animal. This couldn't be

more simple, there is nothing that a draft horse does better than pull, except

of course eat. If the drive motor were instead a generator, I probably

wouldn't hate 6 a.m. feedings as much. There is only one problem with the

idea. Horses get bored walking in a circle so they do have to be driven, but

it is time well spent if they're working off $300 a month in hay.

The final chapter

Today my biggest obstacle seems to be energy storage, not

production. Batteries are expensive and their energy density is not very high.

The methane has extremely high energy density, my major concern is safety. I

don't like a 200-gallon methane bomb on the property. If something were to

happen in an electrical storm for instance, mom would be the proud owner of the

only 40-acre BBQ pit in North America. Compressed air has a mediocre energy

density and if it blows up there would be little damage to anything but the

tank and any surrounding ear drums. I'm going with the compressed air for now.

It is cheap, easy, and safe which makes it the best choice at this time.

My goal is to exceed the energy needs of a normal home and ranch by independent

generation. The second half of my goal is to make the ranch capable of

sustaining itself for up to four weeks in a row. We've got a long way to go but

there has also been a lot of ground covered. Taking one step at a time, I

project that in less than three years the goal can be met. Lately, two

neighbors of Mom's have seen what we are doing and they have asked if I could

help them repeat it on their property. They've also helped out a lot by phone,

when the windmill detonated, Mom was in Chicago and Todd (a neighbor) got the

company to come out and replace it before she returned. Back home there's a

lot of old fashioned-ness and neighbors stay close even if their home is a mile

up the road. I only see room for improvement and a lot of knowledge to be

gained. This was kind of a big gamble and it is paying off, I just hope it

hasn't been all luck.

The land is about 8200 feet in altitude. The Sangre de Cristo range is

across the valley and their peaks climb abruptly to over 14,000 feet within

five lateral miles. This creates a stunningly beautiful view. To the west is

the continental divide again at 14,000 plus feet, but there area good 20 to 30

miles of climb to those peaks. This rugged lay of the land created many

unexpected problems in developing a power system for the house and land. To add

to the problems of the land, cold temperatures are inherent to high altitudes.

I also learned about the unusual wind patterns associated with this country.

Originally I thought this would cause problems but later learned they are a

very predictable energy source.

The land is about 8200 feet in altitude. The Sangre de Cristo range is

across the valley and their peaks climb abruptly to over 14,000 feet within

five lateral miles. This creates a stunningly beautiful view. To the west is

the continental divide again at 14,000 plus feet, but there area good 20 to 30

miles of climb to those peaks. This rugged lay of the land created many

unexpected problems in developing a power system for the house and land. To add

to the problems of the land, cold temperatures are inherent to high altitudes.

I also learned about the unusual wind patterns associated with this country.

Originally I thought this would cause problems but later learned they are a

very predictable energy source. We had a generator put on the land, it was the most reasonable cost and the

fastest to get. The power line was going to take at least two months. The

generator is run on LP that is brought out on a typical propane truck. Although

the generator is very reliable it is also very expensive to run 24 hours a day

As I will explain later, storing the generator's electricity in batteries is

not a good method either The construction was done using the generator, it

worked extremely well The LP we burned ran over $ 100 a week and the generator

only ran during the day. Solar power is not uncommon in the valley and mom

liked the idea of no electric bill, however, the initial investment was not to

her liking. After some convincing, I showed her that the biggest bang for the

buck was solar and we went with that idea.

We had a generator put on the land, it was the most reasonable cost and the

fastest to get. The power line was going to take at least two months. The

generator is run on LP that is brought out on a typical propane truck. Although

the generator is very reliable it is also very expensive to run 24 hours a day

As I will explain later, storing the generator's electricity in batteries is

not a good method either The construction was done using the generator, it

worked extremely well The LP we burned ran over $ 100 a week and the generator

only ran during the day. Solar power is not uncommon in the valley and mom

liked the idea of no electric bill, however, the initial investment was not to

her liking. After some convincing, I showed her that the biggest bang for the

buck was solar and we went with that idea.  On the land I have my mustang, and Mom

has our draft team and two other riding horses. The water consumption of these

monsters is unbelievable To satisfy this need I required up to 50 gallons per

day. An electric water pump was not efficient enough for the needs. It also

drained too much from the solar array. In response to this we found a

pneumatic pump that looked perfect for the job. To power the pump we bought a

windmill that ran an air compressor. The well water was 57 feet below the

surface but the pump only required 40 psi to run. The water is stored in a

1500 gallon cistern that was placed in the basement of the house before

construction. Originally, this was left as an open running system. Whenever

the wind blew, the pump ran and filled the cistern. Later I will explain the

potential I found in this source.

On the land I have my mustang, and Mom

has our draft team and two other riding horses. The water consumption of these

monsters is unbelievable To satisfy this need I required up to 50 gallons per

day. An electric water pump was not efficient enough for the needs. It also

drained too much from the solar array. In response to this we found a

pneumatic pump that looked perfect for the job. To power the pump we bought a

windmill that ran an air compressor. The well water was 57 feet below the

surface but the pump only required 40 psi to run. The water is stored in a

1500 gallon cistern that was placed in the basement of the house before

construction. Originally, this was left as an open running system. Whenever

the wind blew, the pump ran and filled the cistern. Later I will explain the

potential I found in this source.

Solder, one iron, copper wire strands, super

glue and of course duct tape were all I needed to repair the old array. Mom

later purchased six more panels from a local auction for an incredible price.

After all was said and done the array was 14 feet long, 4 feet tall and

generated over 20 amps in direct sunlight. The windmill capable of 250 psi

was set up and ran well. It fed compressed air into what used to be a

40-gallon propane tank. The tank compensated for the times when wind was

scarce. If the tank was fully pressurized to the 250 psi rating, it could

almost fill the 1500 gallon cistern once. In the last year we only had to rely

on the tank three or four times. For security's sake mom bought an electric air

compressor and added tire type inflation hardware, and it has come in handy.

One of the draft horses was able to crush the small pipe that the well's air

line ran through. This cut the air line and bled the tank dry in five

minutes, I can't believe all the elements we've had to protect all the systems

from.

Solder, one iron, copper wire strands, super

glue and of course duct tape were all I needed to repair the old array. Mom

later purchased six more panels from a local auction for an incredible price.

After all was said and done the array was 14 feet long, 4 feet tall and

generated over 20 amps in direct sunlight. The windmill capable of 250 psi

was set up and ran well. It fed compressed air into what used to be a

40-gallon propane tank. The tank compensated for the times when wind was

scarce. If the tank was fully pressurized to the 250 psi rating, it could

almost fill the 1500 gallon cistern once. In the last year we only had to rely

on the tank three or four times. For security's sake mom bought an electric air

compressor and added tire type inflation hardware, and it has come in handy.

One of the draft horses was able to crush the small pipe that the well's air

line ran through. This cut the air line and bled the tank dry in five

minutes, I can't believe all the elements we've had to protect all the systems

from.

This was determined simply by disconnecting the array after a

full charge. One very nice option to the controller is a feature that allows

the bank to be charged by our 110 volt ac generator This is an expensive

process however. Gas cost has already been mentioned The other problem is that

"hard charging" by the generator greatly diminishes the life expectancy of the

batteries. The customer rep that I talked to said that regularly hard charging

the batteries will cut their life by more than half. The high current is the

cause, the array is basically a 'trickle charge" and is far friendlier to the

bank of batteries

This was determined simply by disconnecting the array after a

full charge. One very nice option to the controller is a feature that allows

the bank to be charged by our 110 volt ac generator This is an expensive

process however. Gas cost has already been mentioned The other problem is that

"hard charging" by the generator greatly diminishes the life expectancy of the

batteries. The customer rep that I talked to said that regularly hard charging

the batteries will cut their life by more than half. The high current is the

cause, the array is basically a 'trickle charge" and is far friendlier to the

bank of batteries

Another use of available space came to me when 1 noticed that the barn roof

faced directly south and was built using 2x8 rafter beams. With this kind of

support the roof could easily accommodate the weight of several hundreds of

pounds of solar heat collection panels. These panels are typically 4x8 sheets

covered by traversing PVC tubes The tubes are painted or dyed black and carry

water. Sides are built around the perimeter and a sheet of glass or Plexiglas

encases the tubes. As the sun shines into this miniature greenhouse, it heats

the tubes and therefore the water in them. One small water pump can be run off

an accompanying photovoltaic solar cell. The water is pumped through and the

heat is stored in either a huge water reservoir or it can be used to run an

extremely small scale steam turbine generator. For the ranch, I like the heat

storage idea. The horses would love a warm place to get out of the frigid

winter air and it could reduce the need in the house to burn wood which causes

pollution. I'm not throwing out the steam generator idea yet but I'll need a

lot more information and resources before I attempt tapping that energy

Another use of available space came to me when 1 noticed that the barn roof

faced directly south and was built using 2x8 rafter beams. With this kind of

support the roof could easily accommodate the weight of several hundreds of

pounds of solar heat collection panels. These panels are typically 4x8 sheets

covered by traversing PVC tubes The tubes are painted or dyed black and carry

water. Sides are built around the perimeter and a sheet of glass or Plexiglas

encases the tubes. As the sun shines into this miniature greenhouse, it heats

the tubes and therefore the water in them. One small water pump can be run off

an accompanying photovoltaic solar cell. The water is pumped through and the

heat is stored in either a huge water reservoir or it can be used to run an

extremely small scale steam turbine generator. For the ranch, I like the heat

storage idea. The horses would love a warm place to get out of the frigid

winter air and it could reduce the need in the house to burn wood which causes

pollution. I'm not throwing out the steam generator idea yet but I'll need a

lot more information and resources before I attempt tapping that energy The wind energy potential of this area is truly surprising. I

tried to spend a couple of days doing nothing but vacationing and found I

couldn't. I got up at 6 a.m. to feed the horses. The air was crisp, cold, and

fresh, and not moving. Not good when you need wind to run windmills. By 7 a.m.

the sun was shining on the peaks to the west and I noticed there was an eight

to 15 mph westerly wind within about half an hour. In the evening the opposite

happened, an easterly wind began within half an hour of the sun setting behind

the peaks. After a week of the same pattern I realized it was convection

currents of the air in the mountain valley. Even on calm days this wind is

there in the morning and afternoon. The area is also known for gale force winds

due to the funnel effect the valley has on weather patterns. Last month the

compressor on the windmill was detonated when the high wind break-off on the

mill failed and allowed the blades and compressor to critically over speed.

The unit was replaced at the cost of the manufacturer due to a construction

defect. The potential of this wind has given me two ideas I'm pursuing.

The wind energy potential of this area is truly surprising. I

tried to spend a couple of days doing nothing but vacationing and found I

couldn't. I got up at 6 a.m. to feed the horses. The air was crisp, cold, and

fresh, and not moving. Not good when you need wind to run windmills. By 7 a.m.

the sun was shining on the peaks to the west and I noticed there was an eight

to 15 mph westerly wind within about half an hour. In the evening the opposite

happened, an easterly wind began within half an hour of the sun setting behind

the peaks. After a week of the same pattern I realized it was convection

currents of the air in the mountain valley. Even on calm days this wind is

there in the morning and afternoon. The area is also known for gale force winds

due to the funnel effect the valley has on weather patterns. Last month the

compressor on the windmill was detonated when the high wind break-off on the

mill failed and allowed the blades and compressor to critically over speed.

The unit was replaced at the cost of the manufacturer due to a construction

defect. The potential of this wind has given me two ideas I'm pursuing.