Auburn University partners with Huntsville-based IS4S to produce emergency ventilators

Published: Apr 17, 2020 8:00 AM

By Jeremy Henderson

The RE-InVENT system, an emergency CPAP-to-ventilator converter created by a team of engineers from Auburn University, Integrated Solutions for Systems (IS4S), and the University of Alabama at Huntsville, may join the fight against COVID-19 sooner rather than later.

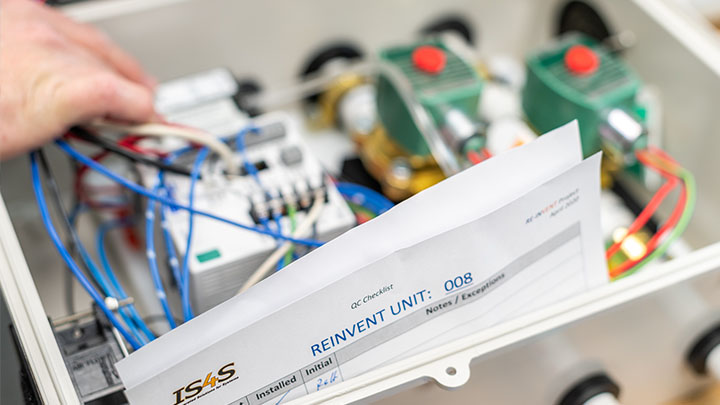

Huntsville-based IS4S, an integrated systems solutions company and defense contractor that frequently partners with Auburn University's Samuel Ginn College of Engineering, has begun production on the innovative accessory, which was developed to mitigate possible ventilator shortages across the country.

A team of 14 IS4S engineers and support staff assembled 100 RE-InVENT units in just three days late last week.

"We’ve worked with IS4S on multiple projects for years," said assistant mechanical engineering professor Michael Zabala, who helped lead the RE-InVENT project. "Because of our great partnership with IS4S, we have been able to move extremely fast toward building the first 100 units, and ultimately towards getting them to those who need them."

Several medical facilities — both national and international — preparing for worst-case coronavirus patient load scenarios have reached out to the RE-InVENT team for possible assistance.

“IS4S was tracking on the RE-InVENT project from the earliest days, and we knew that the need for these devices was urgent and pressing," said Ryan Hill, an IS4S research engineer who earned his bachelor's and master's degree from Auburn in mechanical engineering in 2008 and 2011, respectively. Ryan played an active role on the engineering team that developed and refined RE-InVENT.

Currently in its third iteration, RE-InVENT has twice been tested on live animals, with both tests underscoring the device's design and efficacy as a backup option in the absence of a conventional ventilator.

"While many companies across the country are building ventilators, we thought few could assemble and produce the needed devices in under a week when sources indicated the peak local resource usage would occur," Hill said. "Once the successful animal test was completed, IS4S immediately began taking the steps to fabricate the units for eventual distribution."

On Friday, April 3, a 200-pound male Boer goat with a lung capacity similar to that of humans was anesthetized and ventilated with a RE-InVENT system for approximately two hours in Auburn’s College of Veterinary Medicine’s Vaughan Large Animal Teaching Hospital.

“It went better than I expected in being able to ventilate the animal,” said Glenn Woods, an anesthesiologist affiliated with multiple Alabama hospitals who monitored the test.

The test on a live sheep one week later was just as promising.

"The second test allowed us to not only validate the booster box accessory for RE-InVENT, but gave us further evidence of the capability and performance of the system under conditions that might be similar to what is seen in those battling COVID-19," Zabala said.

Hill said IS4S will spend this week readying the current stock of RE-InVENT devices for eventual distribution.

"We have already received requests from a number of hospitals, and our goal is to obtain appropriate approvals so that we can begin deploying the units," Hill said.

Media Contact: , jdh0123@auburn.edu, 334-844-3591

Developed to mitigate possible ventilator shortages across the country, the design for the innovative RE-InVENT accessory has been licensed to IS4S, a Huntsville-based defense contractor.