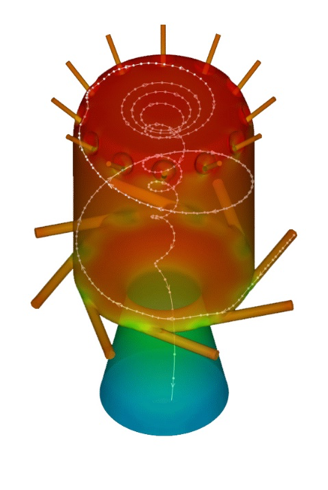

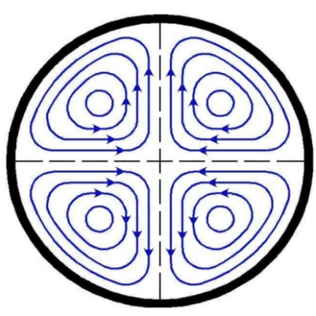

This research thrust is chiefly concerned with combustion chambers in which the fuel and oxidizer gases are swirl-driven. One aspect of our work is focused on the Bidirectional Vortex Engine which is being considered for adoption in next generation shuttle and suborbital vehicles. The corresponding thrust chamber is a liquid-liquid swirl-driven engine that exploits the motion of a cyclonic, bidirectional vortex. This vortex confines hot combustion products to the (inner) core region of a combustion chamber.

The inner vortex is completely surrounded and therefore, shrouded, by an outer layer of freshly injected oxidizer. This low-temperature oxidizer blanket reduces thermal loading, thus allowing for thinner and less costly walls to be used. Due to the spiraling path followed by fuel and oxidizer particles, a longer effective chamber length is engendered. As an added bonus, the spiraling motion increases combustion efficiency by increasing mixing and fuel residence time.

The bidirectional concept was first used in cyclone separators. It has been recently applied to a hybrid rocket engine and is slowly being extended to other internal combustion chambers, liquid-liquid engines, combined-cycle regenerative chambers, and chambers with cryogenic propellants. Despite recent strides along those lines, much work lies ahead.